I will have to cut a bunch (32) of cock beads that are 3" long, 1/4" thick and 3/4" wide. The cuts are 45 degrees, so I'm a bit on the fence about how to accomplish the cuts. The 10" CMS is a bit frightening trying to hold the small pieces against the fence so near the spinning blade. The miter fence on the BT3K's SMT might be OK, but the operation still puts fingers rather close to the blade. My third method would be to cut a miter slot in the fence of my bench hook and cut the pieces with my dovetail saw. Any other methods I haven't thought of?

Small Molding Cutting...

Collapse

This topic is closed.

X

X

-

I had to look up cock beads and I don't think that is what you meant!

However for small parts a band saw is often a good tool.

A hand miter saw or dovetail saw and a miter box if you just have a few.

The Fastcap 10 Million dollar tool is an inexpensive hold down meant for doing small miter saw cuts to keep your hands clear.

https://www.google.com/search?q=10+m...hrome&ie=UTF-8

Loring in Katy, TX USA

Loring in Katy, TX USA

If your only tool is a hammer, you tend to treat all problems as if they were nails.

BT3 FAQ - https://www.sawdustzone.org/forum/di...sked-questions -

I will have to cut a bunch (32) of cock beads that are 3" long, 1/4" thick and 3/4" wide. The cuts are 45 degrees, so I'm a bit on the fence about how to accomplish the cuts. The 10" CMS is a bit frightening trying to hold the small pieces against the fence so near the spinning blade. The miter fence on the BT3K's SMT might be OK, but the operation still puts fingers rather close to the blade. My third method would be to cut a miter slot in the fence of my bench hook and cut the pieces with my dovetail saw. Any other methods I haven't thought of?

For those of us that would rather not get the eventual NSFW results by googling it, would you mind explaining what exactly you mean by "cock beads"?Please like and subscribe to my YouTube channel. Please check out and subscribe to my Workshop Blog.Comment

-

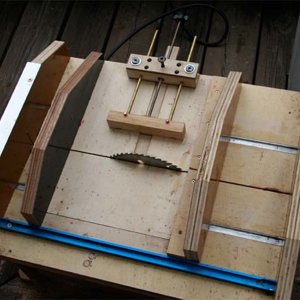

My first general idea is to make a mini sled for the TS. I made one years ago for cutting segments for pens, which requires close proximity to the blade for the fingers. However, due to size reduction of the sled, (2" high backing, 1/4" bottom", approx 6 inch long bed, I had much more control. If you already have a sled, make a jig inside it for handling small pieces. Small pieces like you are wanting are cut on TS regularly, and these cuts are common for experienced pen makers.

For some people, they use a BS for the same process, but the BS does not cut as smoothly as a TS blade. And on smaller pieces, the less smoothness is amplified on BS, to me.Last edited by leehljp; 02-24-2022, 08:26 AM.Hank Lee

Experience is what you get when you don't get what you wanted!

Comment

-

Jim Frye

The Nut in the Cellar.

”Sawdust Is Man Glitter”Comment

-

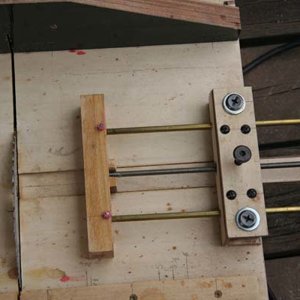

I was not suggesting that you make a sled, but that mini-sleds are what are used to cut some very fine pieces and even repetitive small pieces. The two picts below are from 13 - 14 years ago and that one was pretty good back then. Those sleds and saws have come a long way since then.

A few other more recent jigs (for band saw):

Sometimes the bandsaw is the best tool. It is for cutting wooden ring blanks and often pen blanks. Hands free and safe. I’ll probably add additional wood behind the end of the kerf and maybe use the Microjig stop to end the cut after just the blank is cut. It fits in the miter slot and can be...

Sometimes the bandsaw is the best tool. It is for cutting wooden ring blanks and often pen blanks. Hands free and safe. I’ll probably add additional wood behind the end of the kerf and maybe use the Microjig stop to end the cut after just the blank is cut. It fits in the miter slot and can be...

Well, I've been trying to get better cuts with my bandsaw, and am now starting to make (for the moment very basic, but that will change) segmented pen blanks. The table for my Jet bandsaw is nice and large for its size, but I kept having trouble with the little red disc with the slot in it for...

Well, I've been trying to get better cuts with my bandsaw, and am now starting to make (for the moment very basic, but that will change) segmented pen blanks. The table for my Jet bandsaw is nice and large for its size, but I kept having trouble with the little red disc with the slot in it for...

Hank Lee

Experience is what you get when you don't get what you wanted!

Comment

-

Thanks for the suggestions. I was just down in the shop breaking down the setups from making the base boards on the table project and I think I will add a miter slot to my bench hook and use my little dovetail saw to cut the miters. I'm also planning on mounting the sanding disk on the BT3K for fine tuning the trim pieces.Jim Frye

The Nut in the Cellar.

”Sawdust Is Man Glitter”👍 1Comment

-

I'm obviously having a brain numbing day. I've heard the term "cock bead" and looked it up in one of my books, "The Complete Illustrated Guide to Shaping Wood" by Lonnie Bird (part of Taunton Press's series). On pages 152 and 153 it discusses "cock beads" and shows some illustrations and photos. So after reading the article, I don't exactly visualize what your project pieces look like, "understand how that applies with 32 pieces that are 3" long, 1/4" thick and 3/4" wide, While it's not important that I understand, it does make me wonder,

CWSThink it Through Before You Do!Comment

-

I have this Rockler miter slot sled that is made for 45s. I like that you cut both ends of the wood without changing anything on the sled. It is easy to clamp to, but for tiny mounding you might need to cut on a sacrificial piece so you can hold it down easier and not have it disappear down the blade slot.

Comment

-

Jim, where I am confused and probably a couple of others: If your drawers are, say 16" wide, why are you wanting 3" long pieces at the most? I can't get my mind around that.

Got it. Thanks. You were asking for the short pieces, but I'm thinking you will do it all around; you were asking only about the making of the short pieces.

Cock bead: https://www.woodsmith.com/article/co...eaded-drawers/

I think I did that once on a project (replaced a broken piece) long ago, but did not know what it was called other than edge trim.

I learned something today! Thanks Jim!Last edited by leehljp; 02-25-2022, 09:27 AM.Hank Lee

Experience is what you get when you don't get what you wanted!

Comment

-

I've been thinking of making one of those for my BT3 that attaches to the SMT miter fence.I have this Rockler miter slot sled that is made for 45s. I like that you cut both ends of the wood without changing anything on the sled. It is easy to clamp to, but for tiny mounding you might need to cut on a sacrificial piece so you can hold it down easier and not have it disappear down the blade slot.

I understand that while the miters can be off fractionally from 45 the fact that they are made off a perfect 90 degree set means that the sum of complementary angles made this way will add up to 90 degrees as close as the jig is set.

If you make a series of 45 degree cuts using the miter saw and they each have a 0.1 degree error, by the time you make a picture frame you will be off 0.8 degrees in making the last corner.

Does it really work as well as claimed?

Loring in Katy, TX USA

Loring in Katy, TX USA

If your only tool is a hammer, you tend to treat all problems as if they were nails.

BT3 FAQ - https://www.sawdustzone.org/forum/di...sked-questionsComment

-

I don’t know! Haven’t used this sled yet. Like you said, if one side is off + and the other side is off - everything would work out, but keeping up with a left hand cut and a right hand cut while putting the frame together might be quite challenging.

I have and old Craftsman 4 piece corner clamp set that has one clamp with a miter saw blade guide molded in the casting. I always supposed it was for the last corner where nothing fit real well and it just sawed the mistake out.

-

-

Concerning miter gauge set up. Last week when I was in Rockler I noticed an unusual angle set up block, and while I was fiddling with it one of their staff asked if I knew what it was for. I said I did not have a clue so he showed me. Absolutely genius, on a flat surface you set the block over your miter gauge 3/4” doohickey and adjust your gauge to whichever angle block you picked, 3 different blocks in the set with set up blocks for from 4 to 12 sided frames. The blocks are solid hard plastic so if they are machined properly it would be the cats meow for setting up your miter gauge for picture frames. I’m not advertising for Rockler so you must do you own googling.

Comment

-

Comment

-

I have one of those Craftsman 10 inch sanding disks... somewhere. The original sandpaper became un-stuck after many years so, right now, I have a bare 10 inch metal disk. I never bothered to replace the sandpaper since I have the Ridgid EB4424 belt/spindle sander tool now.

For trimming small miter frame parts, I use a hand plane on a shooting board. I carefully made one that works well for 90 degrees with an add-on piece for 45 degree miters. My luck sanding end grain was poor; using the 10 inch sanding wheel/disk or the EB4424 generally resulted in slightly rounded edges no matter how I tried to hold the workpiece. A shooting board for a block of wood with sandpaper adhered to it worked well when I tried that years ago.

For small miter frame parts another option is to use a large chamfer router bit on a router table. Support the workpiece with a sled and sacrificial backer board. I've had good luck "shaving" a small amount off the end of a workpiece this way to fine-tune the length. For the 3 inch shorty workpieces you plan on making, a small clamp block pinching the workpiece to the sled should work well and make it very safe.

mpc

Comment

Footer Ad

Collapse

Comment