I know it's not a very exciting woodworking project (if you could even call it woodworking), but, I am looking at possibly doing this project to free up floor space and finally (maybe) get the vehicles back into our garage (just had twin girls, and my wife kind of gave the ultimatum):

http://www.familyhandyman.com/DIY-Pr...e/Step-By-Step

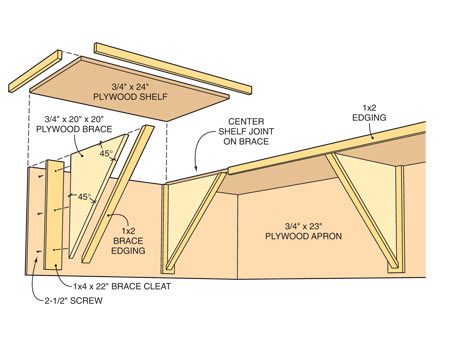

(photo from http://www.familyhandyman.com)

I was wondering if anyone had any opinions on the project. Does the design look solid? Would you change anything about how they were built? Is there an easier / more sturdy way to accomplish this (basically, I want high storage in the garage with 11' ceilings to get stuff off the floor). I was thinking of maybe even doing 2 rows - one 9' high / 2' deep, and one 7' high / 18" deep (where possible), but I'm not sure. The supports for the 7' high shelves might get in the way of getting in and out of the vehicles).

In our last house, I build some high shelves, but they were suspended from the ceiling joists using threaded rods. I like the solution in the Family Handyman article better because it is supported by wall studs, not ceiling joists. Also, the threaded rods got in the way of the stuff I was storing. Finally, I like the idea of the plywood apron to be able to hang stuff off of at any point.

Also, for materials, I was thinking of using a 7-ply softwood from Chile that I saw at HD for $25 (probably the same as this - http://www.bt3central.com/showthread.php?t=50260). Opinions on this choice of plywood? Everything else I've found is either way too expensive, or all knotty/split/etc.

http://www.familyhandyman.com/DIY-Pr...e/Step-By-Step

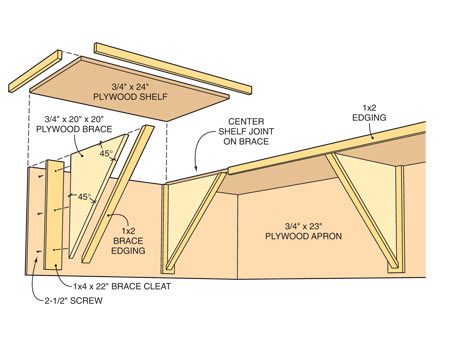

(photo from http://www.familyhandyman.com)

I was wondering if anyone had any opinions on the project. Does the design look solid? Would you change anything about how they were built? Is there an easier / more sturdy way to accomplish this (basically, I want high storage in the garage with 11' ceilings to get stuff off the floor). I was thinking of maybe even doing 2 rows - one 9' high / 2' deep, and one 7' high / 18" deep (where possible), but I'm not sure. The supports for the 7' high shelves might get in the way of getting in and out of the vehicles).

In our last house, I build some high shelves, but they were suspended from the ceiling joists using threaded rods. I like the solution in the Family Handyman article better because it is supported by wall studs, not ceiling joists. Also, the threaded rods got in the way of the stuff I was storing. Finally, I like the idea of the plywood apron to be able to hang stuff off of at any point.

Also, for materials, I was thinking of using a 7-ply softwood from Chile that I saw at HD for $25 (probably the same as this - http://www.bt3central.com/showthread.php?t=50260). Opinions on this choice of plywood? Everything else I've found is either way too expensive, or all knotty/split/etc.

twistsol

twistsol Mine are 17 and I think I got back into the shop when they were about five.

Mine are 17 and I think I got back into the shop when they were about five.

Front supports from either the ceiling or floor have less "open front" but do give more freedom on the shelf for placing of items. I do realize that you are planning only one shelf level, and in that case, the laid out diagram will suffice. But if you want to add a second shelf, the brackets do restrict space on the second shelf.

Front supports from either the ceiling or floor have less "open front" but do give more freedom on the shelf for placing of items. I do realize that you are planning only one shelf level, and in that case, the laid out diagram will suffice. But if you want to add a second shelf, the brackets do restrict space on the second shelf.

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment