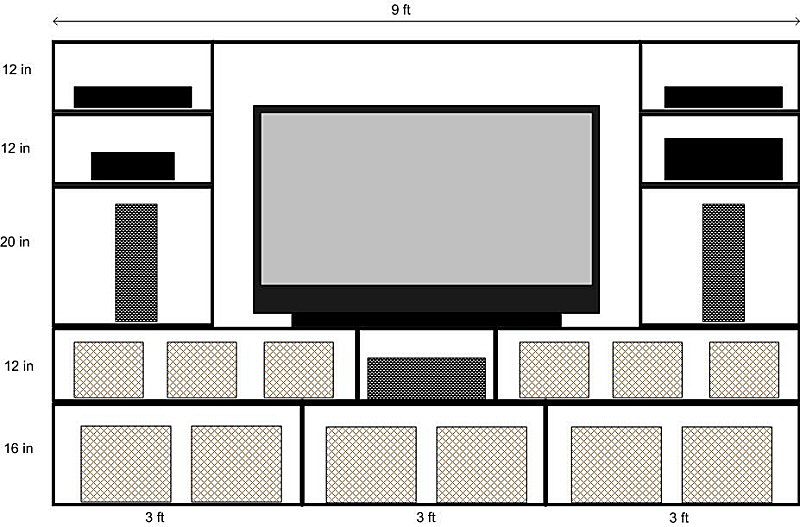

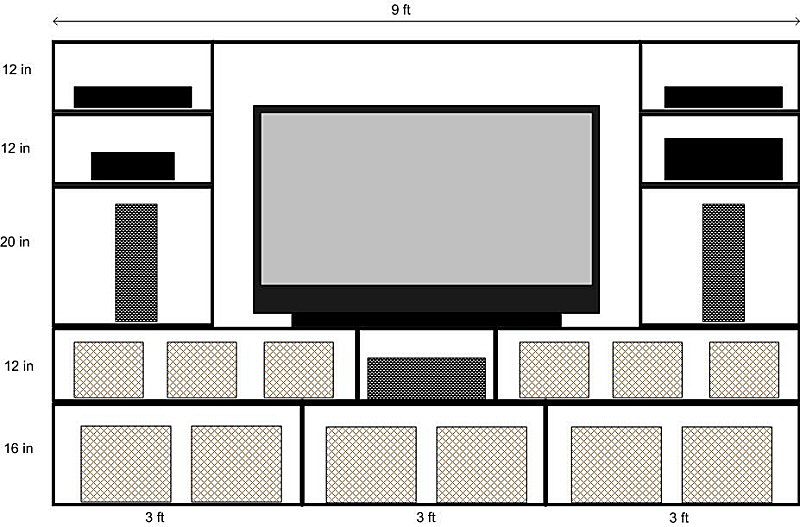

I am planning my first furniture project - an entertainment center. There's a picture below. I plan to use simple boxes everywhere so that's 12 boxes. I considering 3/4 in baltic birch plywood. My wife wants it to be painted black so I don't have to worry about hiding nails or screws. The TV is light (60 lbs) so the main weight will be from the plywood itself. It's 20 inches deep.

How should I join the sides of the boxes to make sure it's strong enough, esp. the bottom two rows of boxes? I don't want it to collapse. Should I consider adding 1x1's to the inside corners for bracing?

In case it matters, I have a BT3100, a small bandsaw and a router with table.

How should I join the sides of the boxes to make sure it's strong enough, esp. the bottom two rows of boxes? I don't want it to collapse. Should I consider adding 1x1's to the inside corners for bracing?

In case it matters, I have a BT3100, a small bandsaw and a router with table.

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment