I'm building the last of nine wall cabinet carcasses, and I'm having trouble with the design. It's one of two corner cabinets, and I used the attached design (with slight modification) to construct the first one. But there are several things different about the second one.

First of all, the one I'm working on now isn't going to be mounted on two intersecting walls; it's going over a peninsula where it meets the wall. The back surface that would normally butt up to the left wall will instead have another face frame and door so the cabinet contents are accessible from the other side of the peninsula. (Both doors will have glass panels so as to not block the natural light from the patio door.) I'm also substituting 1/2 inch ply for the 1/4 inch for the other back, and there obviously won't be a need for the angled back support.

As I've done with all my cabinets, I'll be using dadoes, glue, and screws to attach the top and bottom to the sides. (and the 1/2 inch ply back.) For end panels, where I've been unable to put screws through the sides, I've used pocket screws. I'll be using biscuits to attach the face frames to the cabinet bottoms, and pocket screws for the other three sides. Were it just a matter of adjusting the measurements to account for the 3/4" face frame and the 1/2" ply back, I don't think I'd have too much problem. However, there's another fly in the ointment.

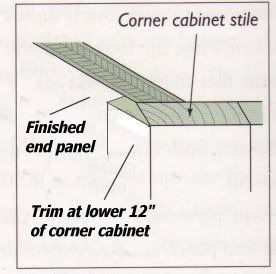

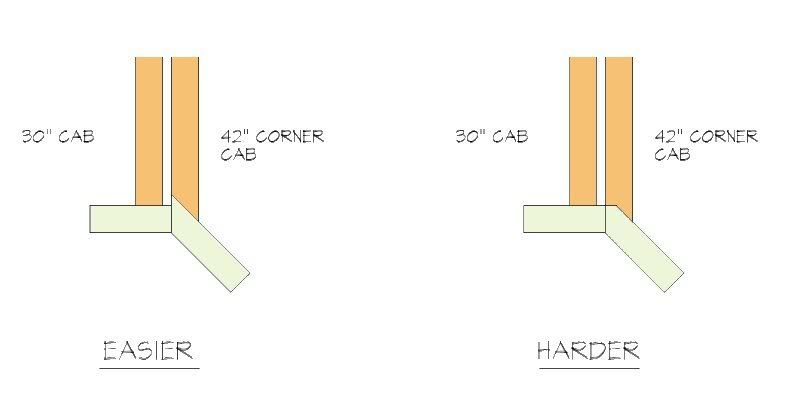

As with the other corner I made, there will be cabinets attached to both sides. The one to the right will be 42" just like the corner; the one to the left, however, will only be 30" because it will be directly above the peninsula (the back of which has an overhang to accomodate stools for dining.) That means at least the bottom 12" of the left side of the corner cabinet will presumably need to be finished as if it were an end panel (ie. flush corners, and no exposed fasteners.) But the end stll has to be the correct size (12" deep) to match the depth of the 30" cabinet, and the angle of the front face frame (45 degrees) has to be maintained.

My head hurts from trying to work this out on my own. Any ideas?

[I tried to upload pictures exported from the design software I use, but they're bitmap files which our forum doesn't tolerate very well. I printed one out in black and white, and scanned it. Better than nothing, I guess. The cabinets I'm referring to are on the left.]

First of all, the one I'm working on now isn't going to be mounted on two intersecting walls; it's going over a peninsula where it meets the wall. The back surface that would normally butt up to the left wall will instead have another face frame and door so the cabinet contents are accessible from the other side of the peninsula. (Both doors will have glass panels so as to not block the natural light from the patio door.) I'm also substituting 1/2 inch ply for the 1/4 inch for the other back, and there obviously won't be a need for the angled back support.

As I've done with all my cabinets, I'll be using dadoes, glue, and screws to attach the top and bottom to the sides. (and the 1/2 inch ply back.) For end panels, where I've been unable to put screws through the sides, I've used pocket screws. I'll be using biscuits to attach the face frames to the cabinet bottoms, and pocket screws for the other three sides. Were it just a matter of adjusting the measurements to account for the 3/4" face frame and the 1/2" ply back, I don't think I'd have too much problem. However, there's another fly in the ointment.

As with the other corner I made, there will be cabinets attached to both sides. The one to the right will be 42" just like the corner; the one to the left, however, will only be 30" because it will be directly above the peninsula (the back of which has an overhang to accomodate stools for dining.) That means at least the bottom 12" of the left side of the corner cabinet will presumably need to be finished as if it were an end panel (ie. flush corners, and no exposed fasteners.) But the end stll has to be the correct size (12" deep) to match the depth of the 30" cabinet, and the angle of the front face frame (45 degrees) has to be maintained.

My head hurts from trying to work this out on my own. Any ideas?

[I tried to upload pictures exported from the design software I use, but they're bitmap files which our forum doesn't tolerate very well. I printed one out in black and white, and scanned it. Better than nothing, I guess. The cabinets I'm referring to are on the left.]

Comment