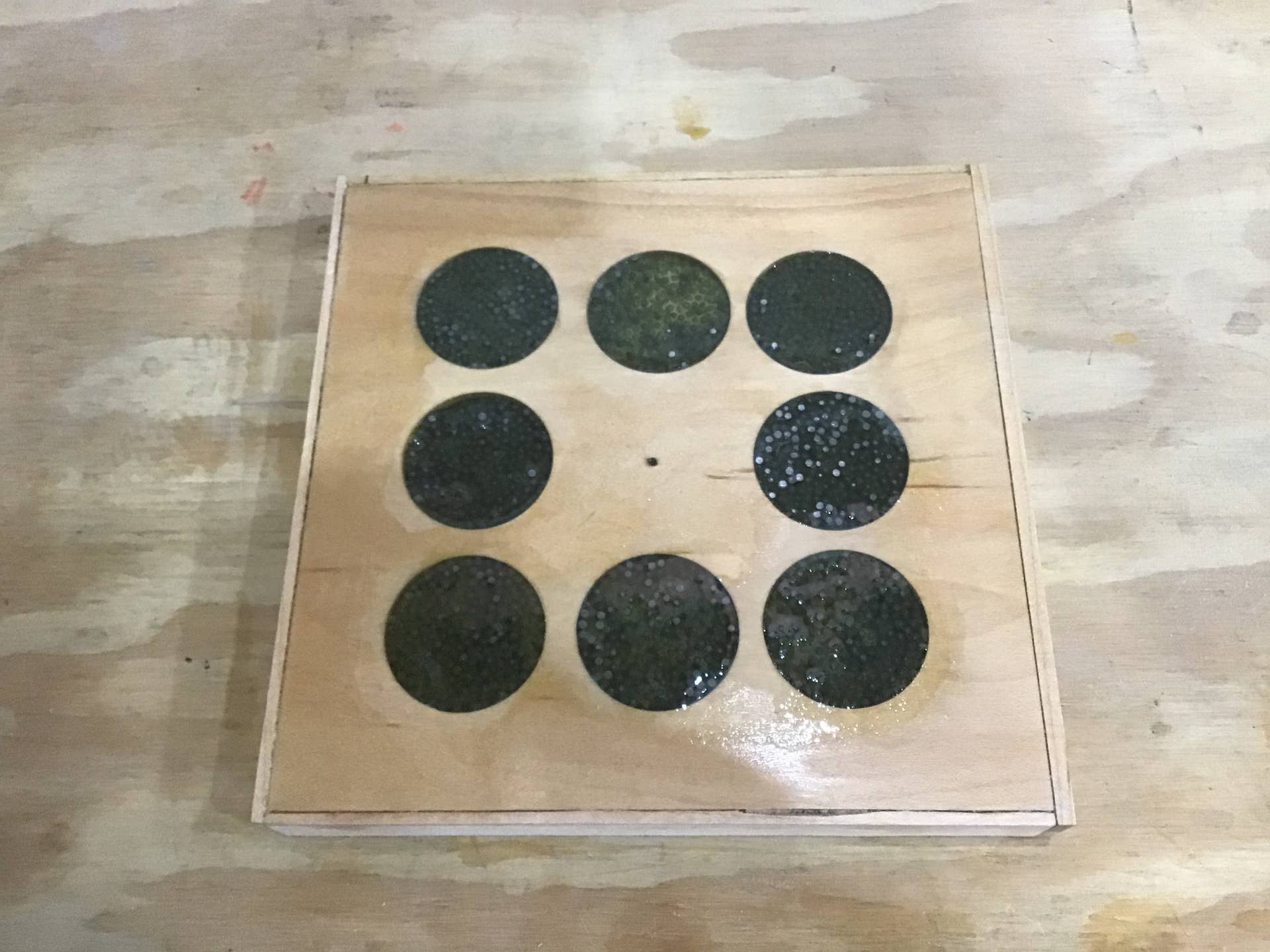

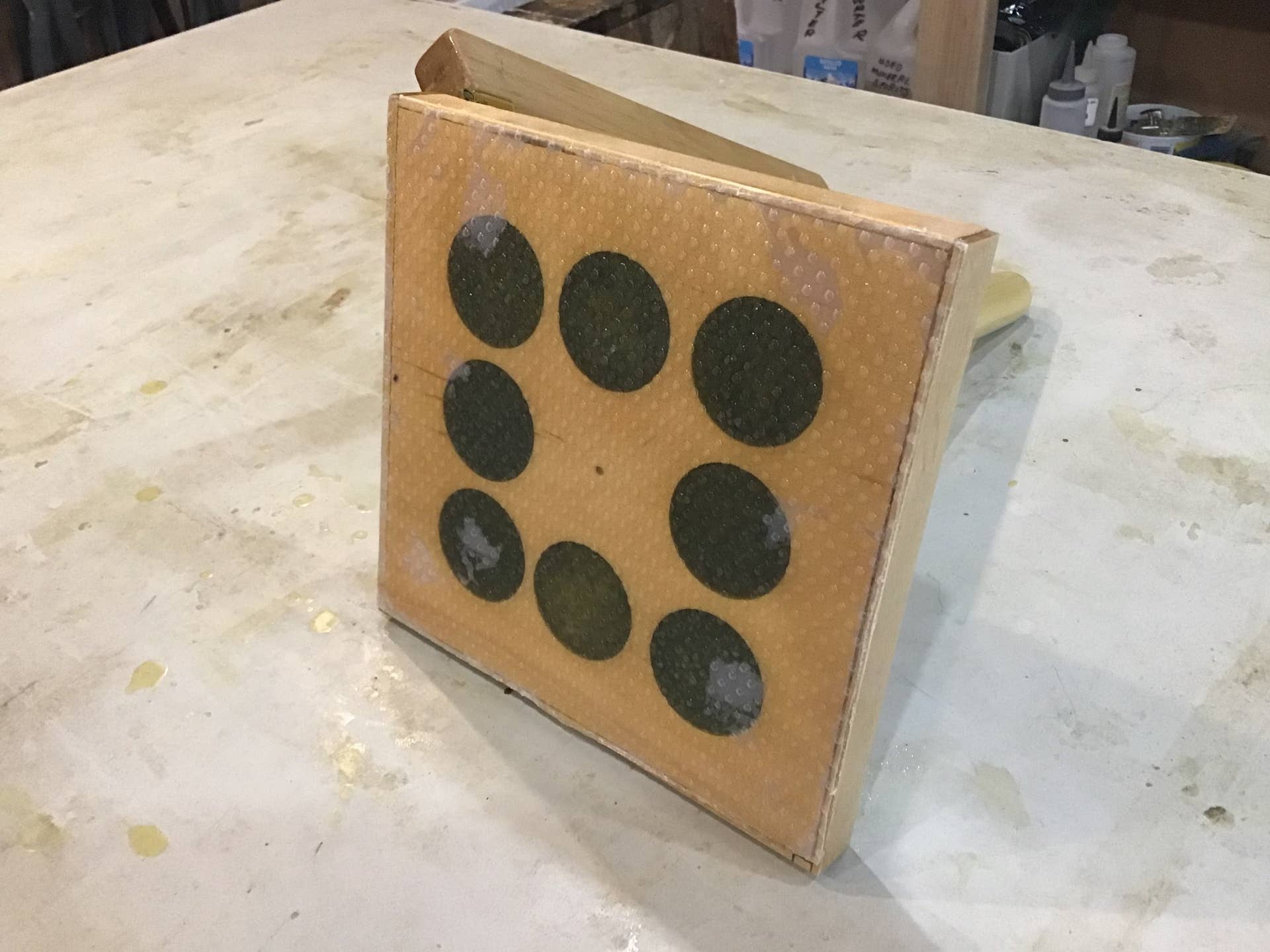

This paper towel holder is for the new laundry room cabinetry. I started with a piece of 3/4" maple veneer plywood and cut it to 6 3/4" square. Then it was edge banded with 1/8" thick maple strips. The commercial holders on the market have bottom weights to stabilize them in use. I bored eight 1 1/2" diameter holes 1/2" deep in the bottom. These recesses each received three teaspoons of #7 1/2 lead shot and were then filled with casting epoxy.

The center post is a scrap piece of 1" diameter dowel. I cut a piece to length and rounded the top end. A 1" diameter hole was bored in the center of the top with a Forstner bit until the center point just broke the surface of the bottom. The dowel was glued into the hole in the top of the base.

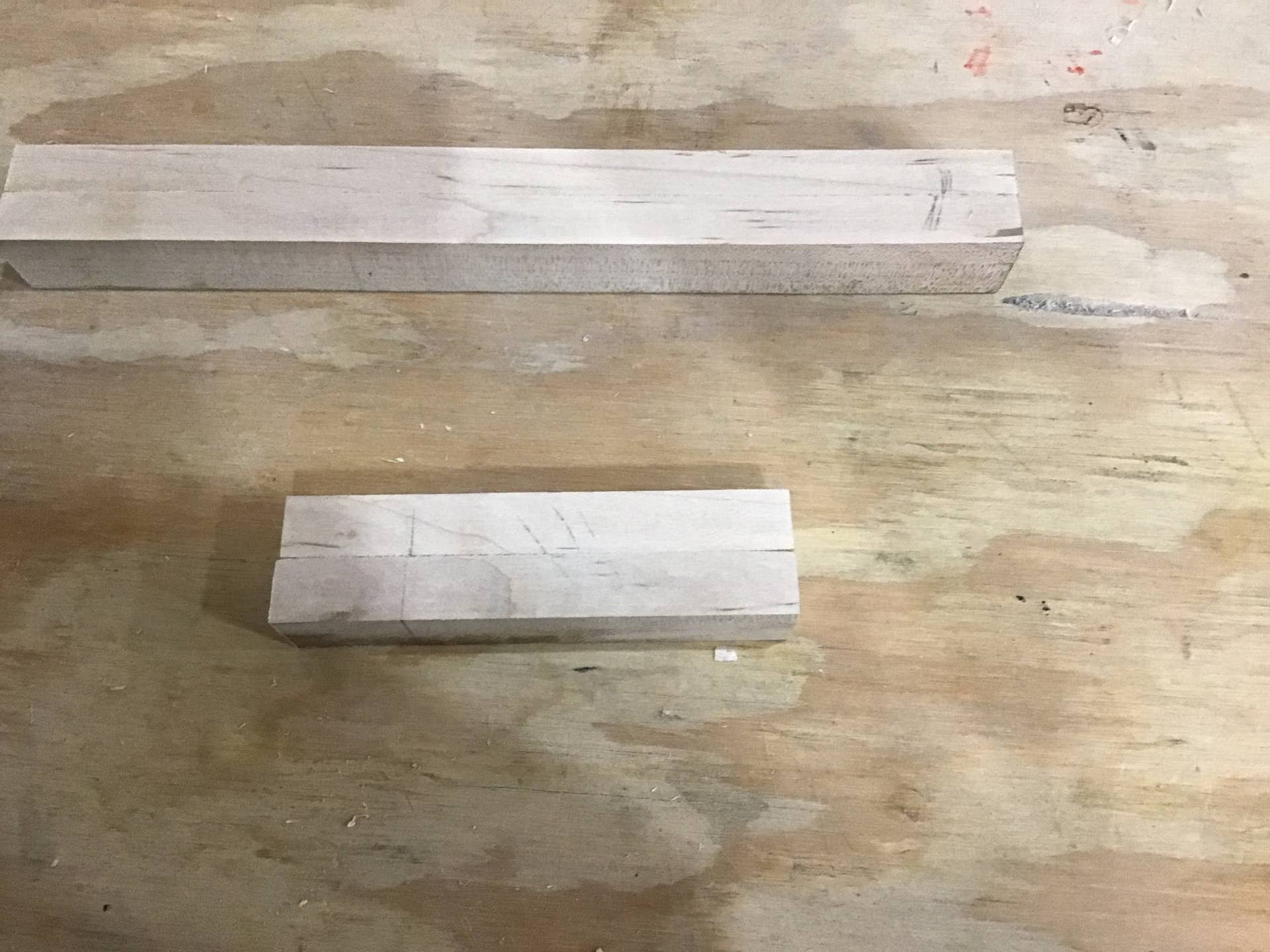

The commercial towel holders often have a spring loaded arm that presses against the roll of towels to allow one handed dispensing. I couldn't figure out an easy way to spring this and didn't have any springs in the shop suitable anyway. I decided to try a weighted arm and pressure pad instead. The pressure pad has weight in the bottom half and the pressure arm has weight in its upper half. The idea was to cause the arm to lean in towards the roll and the pad would hang vertically to press against the roll of towels. I took some maple scraps and ripped them into the sizes needed. I then resawed the arm and pad pieces in half. I used a Forstner bit to create 1/2" wide by 1/4" deep recesses in the halves. The recesses were filled with the lead shot and epoxy. Then the halves were glued back together encasing the lead shot. A bit of shaping and the parts were ready for assembly.

Everything was varnished and I used two small decorative hinges from the junk hardware box to complete the pressure arm. I glued a scrap piece of vinyl shelf liner with the nubby side down to the bottom to give the holder a non-slip base in the cabinet.

The center post is a scrap piece of 1" diameter dowel. I cut a piece to length and rounded the top end. A 1" diameter hole was bored in the center of the top with a Forstner bit until the center point just broke the surface of the bottom. The dowel was glued into the hole in the top of the base.

The commercial towel holders often have a spring loaded arm that presses against the roll of towels to allow one handed dispensing. I couldn't figure out an easy way to spring this and didn't have any springs in the shop suitable anyway. I decided to try a weighted arm and pressure pad instead. The pressure pad has weight in the bottom half and the pressure arm has weight in its upper half. The idea was to cause the arm to lean in towards the roll and the pad would hang vertically to press against the roll of towels. I took some maple scraps and ripped them into the sizes needed. I then resawed the arm and pad pieces in half. I used a Forstner bit to create 1/2" wide by 1/4" deep recesses in the halves. The recesses were filled with the lead shot and epoxy. Then the halves were glued back together encasing the lead shot. A bit of shaping and the parts were ready for assembly.

Everything was varnished and I used two small decorative hinges from the junk hardware box to complete the pressure arm. I glued a scrap piece of vinyl shelf liner with the nubby side down to the bottom to give the holder a non-slip base in the cabinet.

LCHIEN

LCHIEN Loring in Katy, TX USA

Loring in Katy, TX USA

Comment