I've seen and read some of the projects that guys and gals out there do for their shops, that are really just skill builders. I mean really, who needs dovetailed plywood drawers and raised panel doors for shop cabinets when a simple piece of plywood with strap hinges would suffice? So we know we do this, now for the fess up time... What shop projects have you done that helped you build up your skills, or get accustomed to a new piece of equipment?

I am getting there, slowly but surely... Mine so far have been...

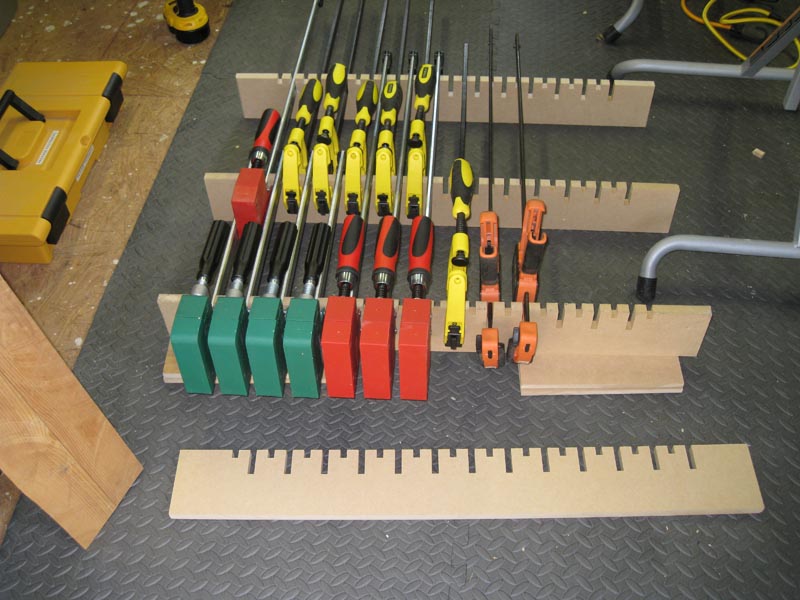

#1. Clamp racks. Got me used to new layout on router table. (Double cove profile cut into the cross bars).

#2. Router Table Rolling Cart. Learned to use pocket screw joinery.

#3. Planer Infeed / Outfeed tables. Cutting square cuts on the table saw, planing to exact thickness, routing, biscuit joinery, screw hole counter sinking.

#4. Thien Cyclone. Routing, cutting circles with a router / jig, rabbeting a circle.

#5. Bandsaw resawing jig. Ripping lumber to exact, and small dimensions on the TS, dadoes, cutting slots with the router.

#6. Plywood push stick. Simple little item, got me plenty of practice cutting curves on the band saw, and sanding on the oscillating sander.

#7. Workbench. I know this sounds silly, but accurate crosscuts with the circular saw, ripping with the circular saw and a straight edge.

There are more skill builder projects, but those are the ones I did for the shop. And of course there are more on the way. A lot of the guys here have gorgeous shops, with shop built cabinets and cases that are to die for. I'm not there yet, and I am not saying any sort of jealousy over the cabinets being done, but rather over the skill level you folks show. I know my skills are improving at a good pace, and would improve faster if I had more time, and $$ to dedicate to shop and home projects...

What were your skill builders? What did you learn or improve? and maybe even, can you post up pics? (Yeah I left pics out because everyone has seen them already...)

I am getting there, slowly but surely... Mine so far have been...

#1. Clamp racks. Got me used to new layout on router table. (Double cove profile cut into the cross bars).

#2. Router Table Rolling Cart. Learned to use pocket screw joinery.

#3. Planer Infeed / Outfeed tables. Cutting square cuts on the table saw, planing to exact thickness, routing, biscuit joinery, screw hole counter sinking.

#4. Thien Cyclone. Routing, cutting circles with a router / jig, rabbeting a circle.

#5. Bandsaw resawing jig. Ripping lumber to exact, and small dimensions on the TS, dadoes, cutting slots with the router.

#6. Plywood push stick. Simple little item, got me plenty of practice cutting curves on the band saw, and sanding on the oscillating sander.

#7. Workbench. I know this sounds silly, but accurate crosscuts with the circular saw, ripping with the circular saw and a straight edge.

There are more skill builder projects, but those are the ones I did for the shop. And of course there are more on the way. A lot of the guys here have gorgeous shops, with shop built cabinets and cases that are to die for. I'm not there yet, and I am not saying any sort of jealousy over the cabinets being done, but rather over the skill level you folks show. I know my skills are improving at a good pace, and would improve faster if I had more time, and $$ to dedicate to shop and home projects...

What were your skill builders? What did you learn or improve? and maybe even, can you post up pics? (Yeah I left pics out because everyone has seen them already...)

Loring in Katy, TX USA

Loring in Katy, TX USA

I found plans in an old Shop Notes and built a big U-shaped workbench with drawers and cabinets. I got to learn how to use my BT3, my router accessory table, and my dado set. I also learned how to build drawers, and panel doors as well as how to make jigs for adjustable shelf holes and drawer/door pulls. I made LOTS of sawdust too!

I found plans in an old Shop Notes and built a big U-shaped workbench with drawers and cabinets. I got to learn how to use my BT3, my router accessory table, and my dado set. I also learned how to build drawers, and panel doors as well as how to make jigs for adjustable shelf holes and drawer/door pulls. I made LOTS of sawdust too!  Someday, I hope to use these skills to remodel my kitchen. I'm not quite comfortable enough to tackle the cabinets, so I need to practice on more shop projects.

Someday, I hope to use these skills to remodel my kitchen. I'm not quite comfortable enough to tackle the cabinets, so I need to practice on more shop projects.

Comment