Does anyone flute/vein columns? What is the best jig? Should I mount the column on centers and use a router? I have 2 lathes ;but, niether are set up. I am thinking this jig should be shaped like a trough. The router mounted to a sled so it can slide across the top edges of the trough. Any pics or more insight would be greatly appreciated! Phil Thanks everyone. I am sorry for not making myself clear. Round (cylindrical) columns with flutes. I look forward to seeing how you did this Larry.

Fluting columns!

Collapse

This topic is closed.

X

X

-

Tags: None

-

Does anyone flute/vein columns? What is the best jig? Should I mount the column on centers and use a router? I have 2 lathes ;but, niether are set up. I am thinking this jig should be shaped like a trough. The router mounted to a sled so it can slide across the top edges of the trough. Any pics or more insight would be greatly appreciated! Phil

I've always used a handheld router with a core box bit. The jig is fairly simple. It's primarily a one piece panel with the center cut out. The inside edges of the long sides are the distance to the first flute cut (for both outside flutes). Then a spacer is placed against the edge to get the second flute (on both sides), etc.

Each pass is made with the left side of the router base against the edge of the jig. IOW, for the left flute, the base is pushed on the left edge, and on the right side the jig can be turned around, or if it's clamped down, walk to the other end and make the pass as the first one was done. Stops can be set at both ends.

.Comment

-

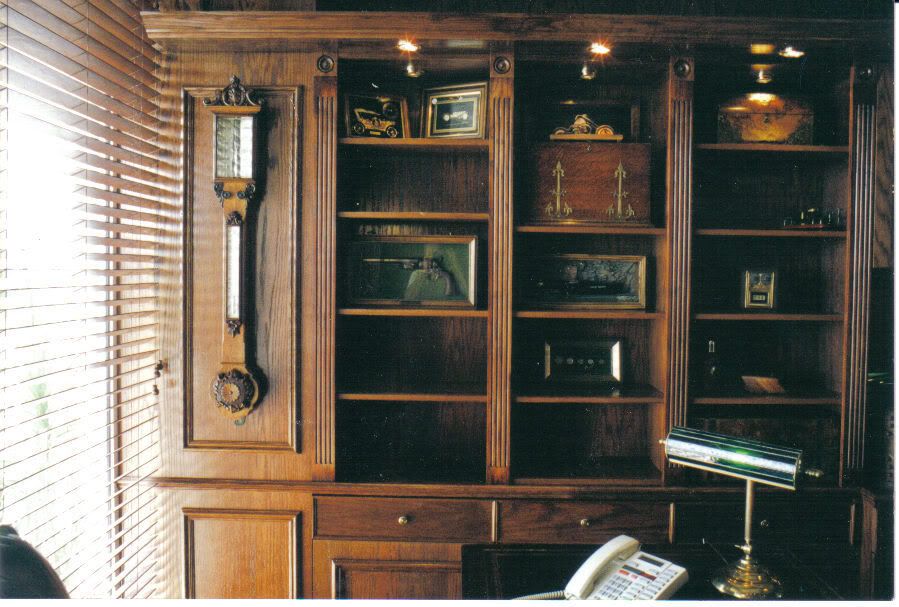

Here are a couple of pictures of some colums I fluted for my son-in-laws front pourch. I use a 1/2 core box bit in my router and my routers edge guide to make the flutes. I used stop blocks on the ends. I cut the center flute first and then worked out. You can cut from both sides of the boards for each flute and only have one setting for each flute.RobertComment

-

I did this column for my kitchen bench and used a core box bit. I built a jig for the router that was a custom base plate and and had 2 guides that ran either side of the column. The router was off-set to the guides. edge guide. I put stops at both ends, ran one flute, turned the base 180 degrees then ran the other. I suggest doing this in multiple passes. If I tried to cut too deep I did not get a smooth bottom on the flute.

David

David

The chief cause of failure in this life is giving up what you want most for what you want at the moment.Comment

-

-

Round columns, right? (You mentioned a lathe, and mounting the column between centers.) Cutting flutes in square columns is dead easy. Round ones, not so much.

I'll send you a PM with some pics of a fixture I built for a similar purpose. It's probably too small for your purposes but the concept is exactly the same.LarryComment

-

-

I have not yet done this, but I've thought on it a bunch. I figured some form of router sled that can ride in the channel of the lathe bed would be the way to go, if you have indexing on your lathe.

If not you may have to make something more sophisticated.Keith Z. Leonard

Go Steelers!Comment

-

I am in the middle of a build that requires flutes on flat surfaces like robk's columns. It is actually plant stands of various heights for patios, weddings etc. I have the table saw set up with an angle jig, and cut 3/4 wide x 3/8 deep coves. There are numerous cove cutting web sites that show this in great detail. One of the better sites is the woodgear site. Somewhere I saw a jig built to use on too large to handle on a table saw pieces that used a circular saw rather than a router. It allowed a variety of larger cove sizes without having to buy expensive router bits. I have had good luck cutting coves on the table saw.

capncarlComment

-

Are the flutes in your columns going to end within the work piece, or extend to the end of the piece? I would expect that flutes done with a TS or circular saw would not have a very elegant termination.I am in the middle of a build that requires flutes on flat surfaces like robk's columns. It is actually plant stands of various heights for patios, weddings etc. I have the table saw set up with an angle jig, and cut 3/4 wide x 3/8 deep coves. There are numerous cove cutting web sites that show this in great detail. One of the better sites is the woodgear site. Somewhere I saw a jig built to use on too large to handle on a table saw pieces that used a circular saw rather than a router. It allowed a variety of larger cove sizes without having to buy expensive router bits. I have had good luck cutting coves on the table saw.

capncarlComment

-

If done on the TS with a moulding head, setting up marks to start and terminate the flutes will leave curvatures, which look fine. It may take running the flute to the rear mark and then backing up the column to the forward mark.

My complaints with this process is you can't see what you're doing, and having to hold the entire run to the fence and holding down.

.Comment

-

Ahhh.. I was thinking of the "diagonal feed method"If done on the TS with a moulding head, setting up marks to start and terminate the flutes will leave curvatures, which look fine. It may take running the flute to the rear mark and then backing up the column to the forward mark.

My complaints with this process is you can't see what you're doing, and having to hold the entire run to the fence and holding down.

.Comment

-

Anyone else?

Has anyone done /or have seen someone else flute large DIA. cylindrical columns (front of house type)???????? Dear drumpriest, You mentioned you have thought about this alot. Have you sketched any kind of jig? Phil

Comment

Footer Ad

Collapse

aiyou

aiyou

Comment