Hi,

I'm making a pair of raised panel doors for a cabinet and need some advice before I start. The bit I chose is the MLCS Ogee with Bead Raised Panel Router Bit. The panel is made of red oak. I've cut some bead and picture frame molding of the same material and it is very hard to route. With those smaller bits I could only cut less than 1/8" depth/pass with the piece held firmly with vertical and horizontal feather boards.

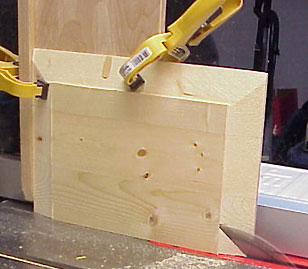

I did a practice piece with the panel bit and found I needed to cut 1/16" or less per pass. But I see a couple problems. The first is the panel will be too big to allow the horizontal feather board so I would have to hold the piece against the fence and bit by hand. Second, I'm changing the depth of the router each cut instead of leaving it fixed and using shims under the piece as I've read about.

I've seen a gadget on the MLCS website that holds a vertical feather board offset a few inches from the fence. I suppose that would help with a large panel but still worry that holding it by hand in the horizontal axis would let it kick back. Controlling the depth of the cut, it seems like a stack of shims (its a pretty deep profile) would just make the stability of the piece worse and not work as well as changing the router depth.

I'd appreciate any advice on the best way to do this first raised panel project. I'm pretty happy with the panels I made planing and biscuit joining and don't want to attempt milling the profile till I know what I'm doing on that step.

Thanks

Chris

I'm making a pair of raised panel doors for a cabinet and need some advice before I start. The bit I chose is the MLCS Ogee with Bead Raised Panel Router Bit. The panel is made of red oak. I've cut some bead and picture frame molding of the same material and it is very hard to route. With those smaller bits I could only cut less than 1/8" depth/pass with the piece held firmly with vertical and horizontal feather boards.

I did a practice piece with the panel bit and found I needed to cut 1/16" or less per pass. But I see a couple problems. The first is the panel will be too big to allow the horizontal feather board so I would have to hold the piece against the fence and bit by hand. Second, I'm changing the depth of the router each cut instead of leaving it fixed and using shims under the piece as I've read about.

I've seen a gadget on the MLCS website that holds a vertical feather board offset a few inches from the fence. I suppose that would help with a large panel but still worry that holding it by hand in the horizontal axis would let it kick back. Controlling the depth of the cut, it seems like a stack of shims (its a pretty deep profile) would just make the stability of the piece worse and not work as well as changing the router depth.

I'd appreciate any advice on the best way to do this first raised panel project. I'm pretty happy with the panels I made planing and biscuit joining and don't want to attempt milling the profile till I know what I'm doing on that step.

Thanks

Chris

Loring in Katy, TX USA

Loring in Katy, TX USA

Black wallnut

Black wallnut

Comment