Good day

I would like to share with you an idea that was "sitting" in my head for long time and yesterday, I made it.

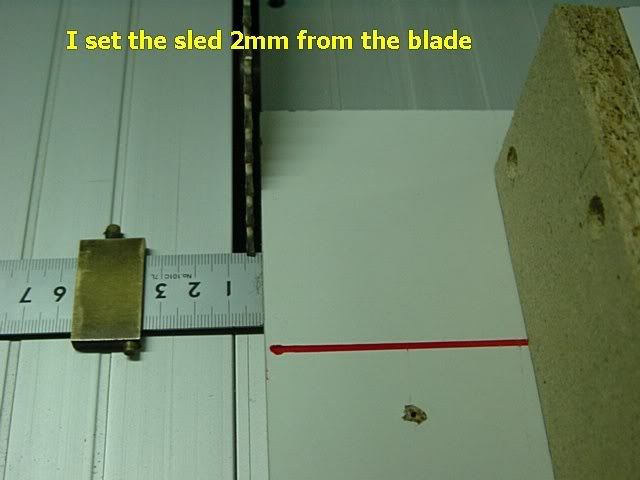

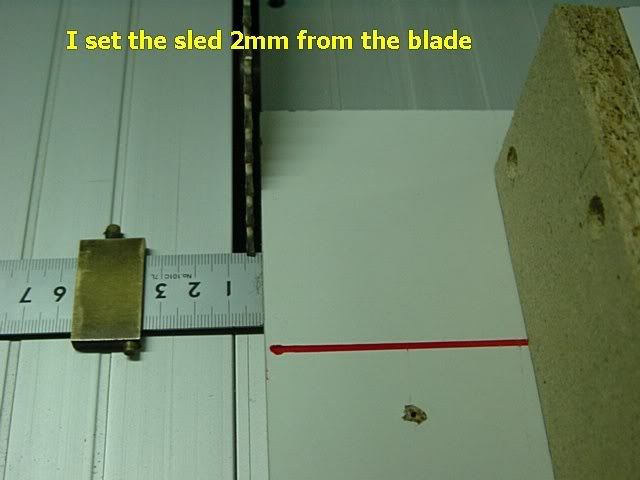

The title is "2 mm" (5/64") because I tested it by cutting 2mm strips but, it can be any thickness of strips....even less...

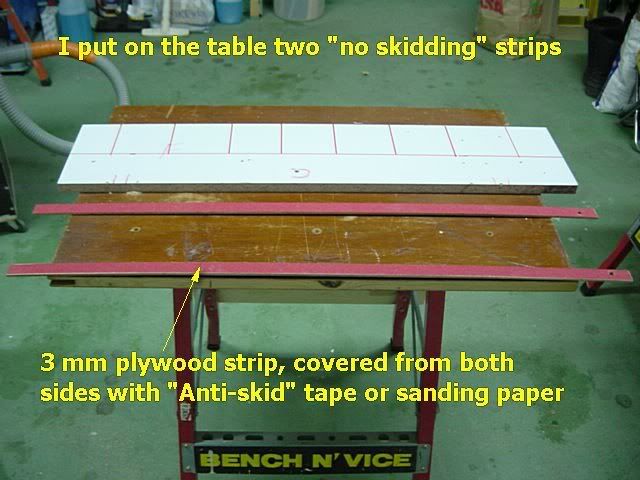

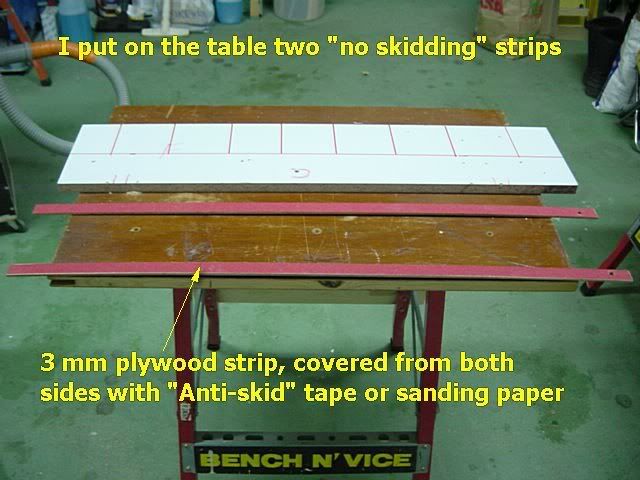

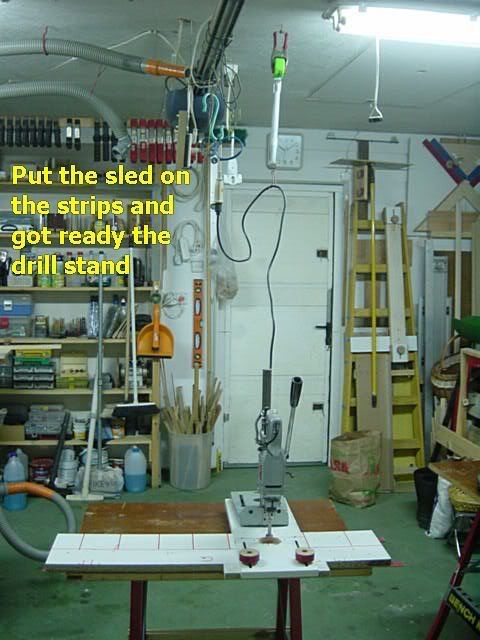

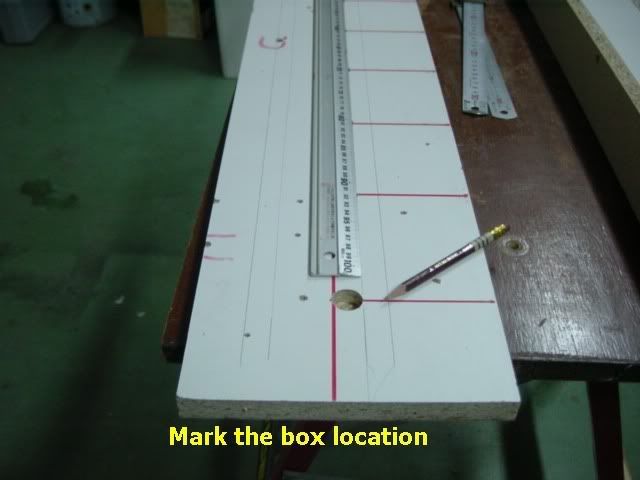

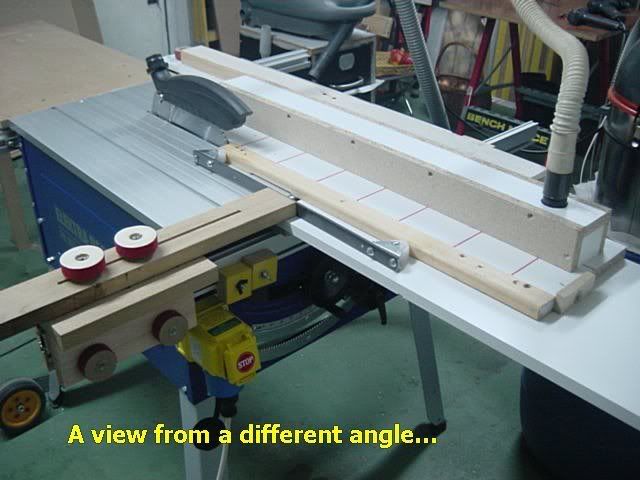

So...the sled is an 3/4" Melamine board 36" long and 8" wide but, you choose yours.

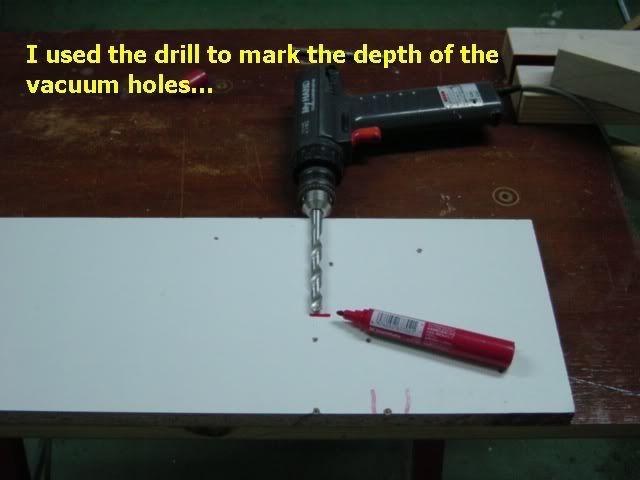

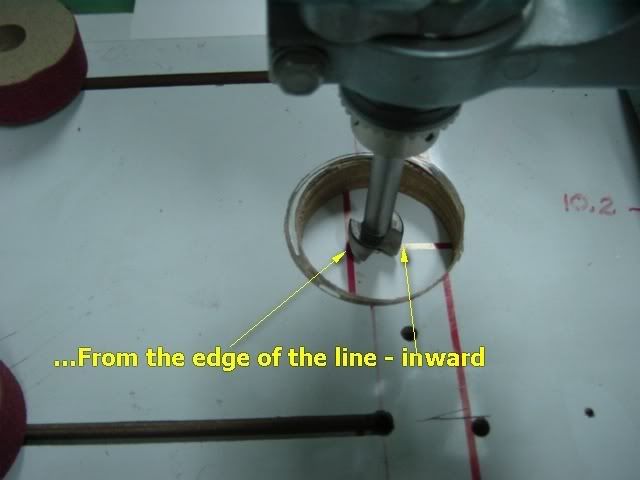

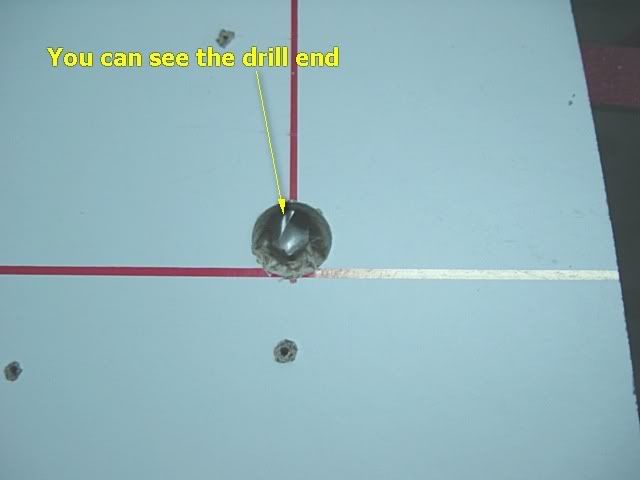

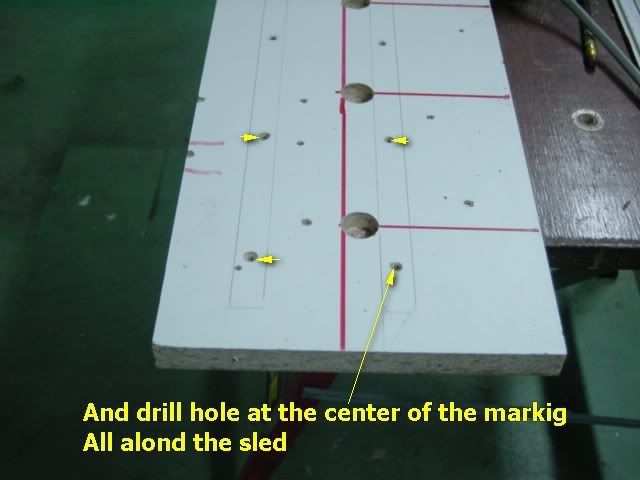

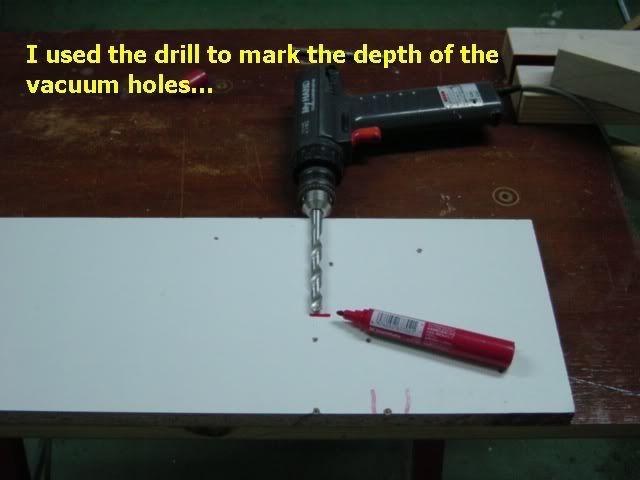

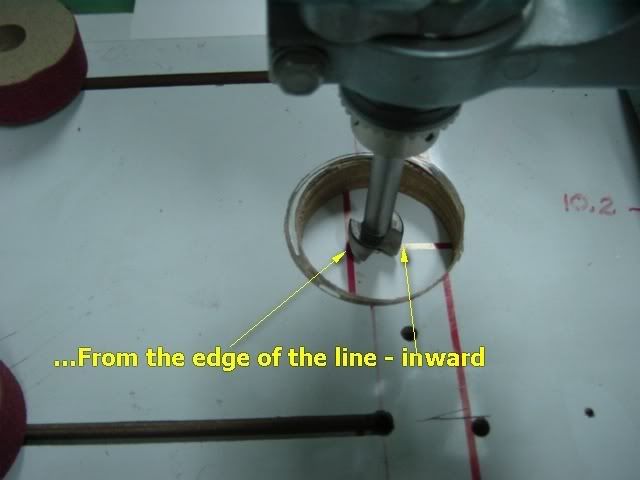

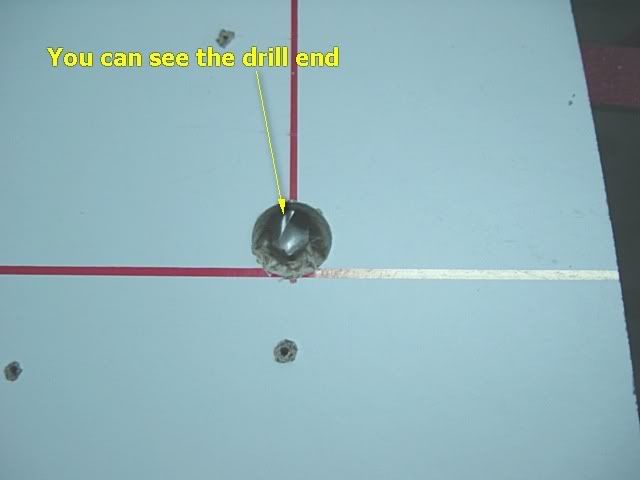

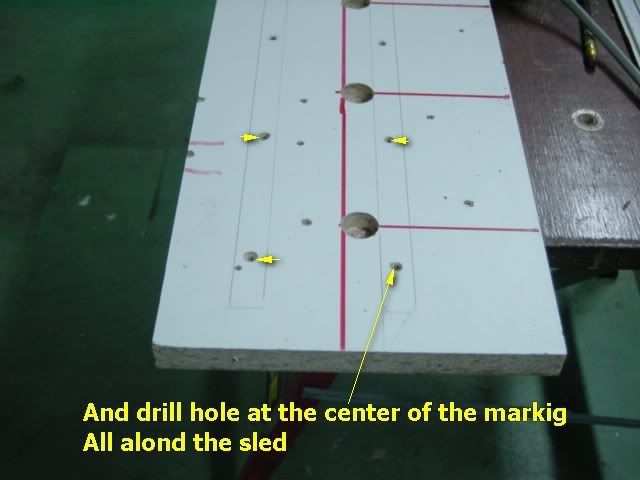

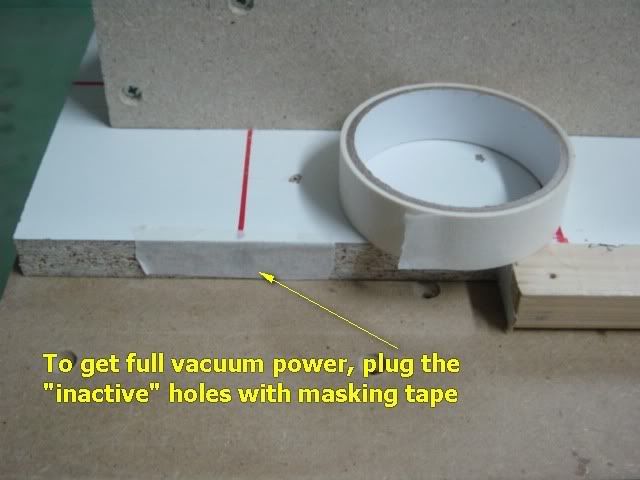

I drilled 3/8" "Vacuum holes" but first I drilled 1/4" as a pilot hole (easier to control the drill) and than went with the 3/8" drill bit to the end of the drill length

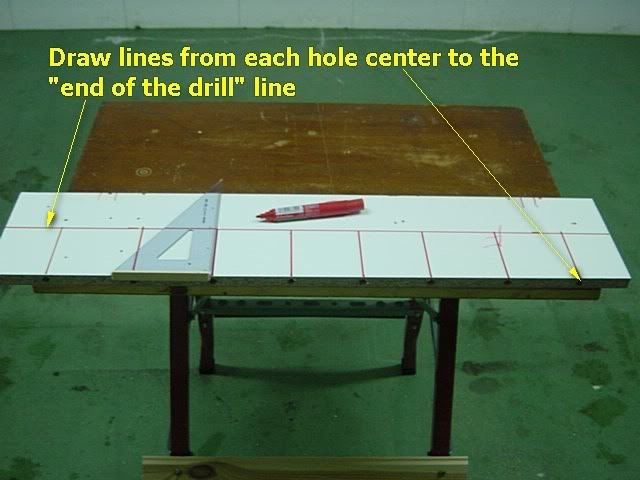

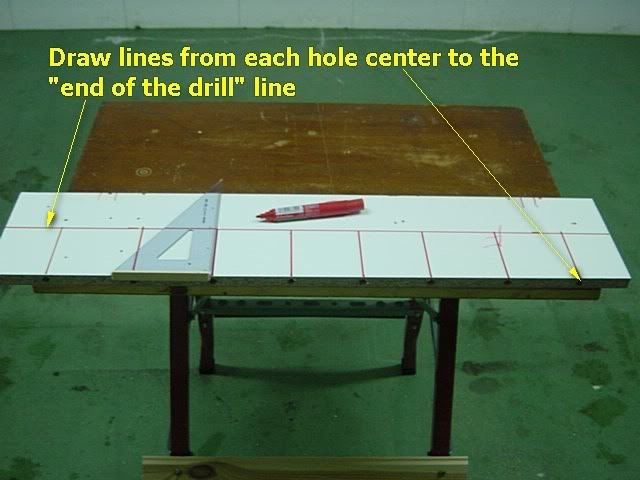

I drilled the holes at 4" intervals but I think that the more holes, the better (say, every 2½"~3") even though, I did not have any problems with the vacuum pressure.

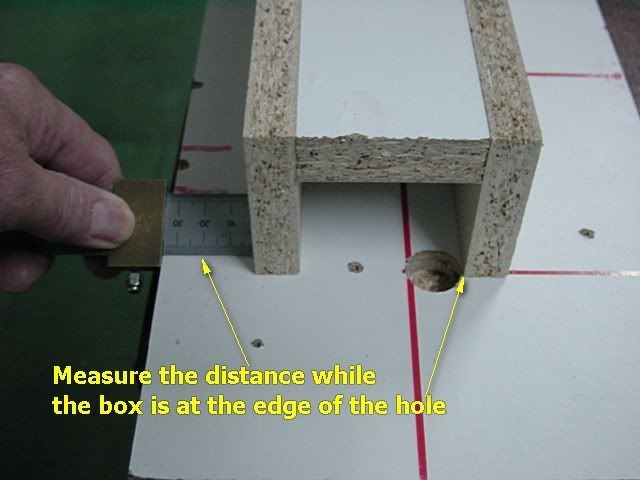

I drilled 3/4" hole dia at the "end of the drill line"

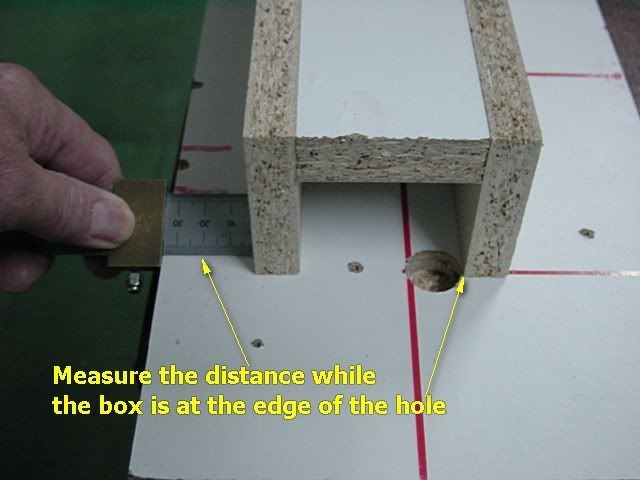

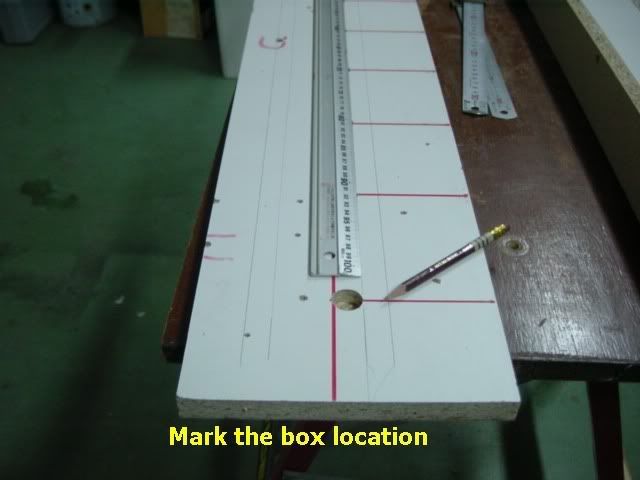

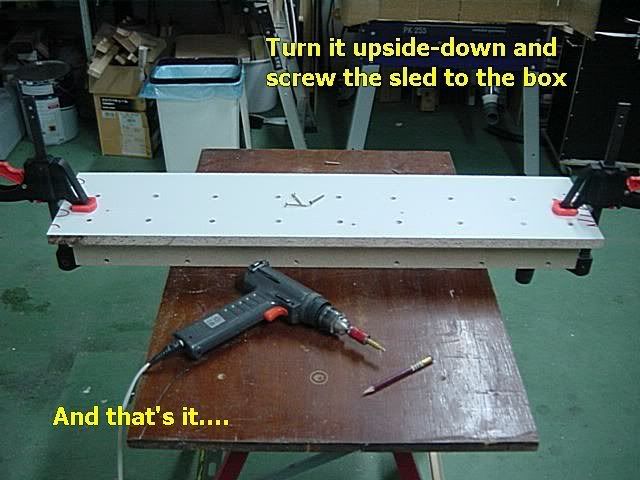

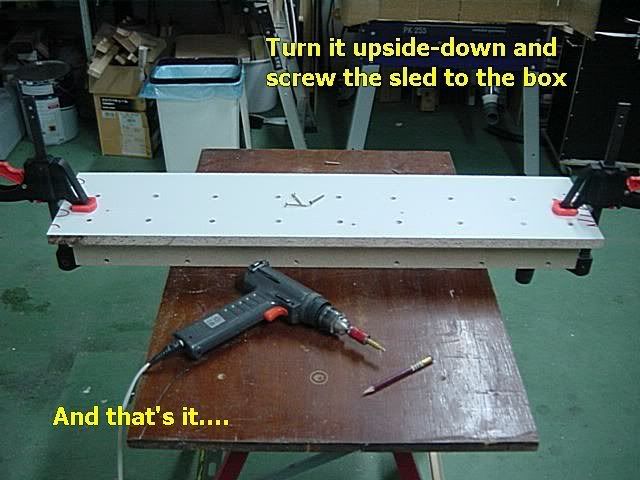

The "Box" can be made of anything...I made it from pieces of chip-board and Melamine (that's what I found in the attic)

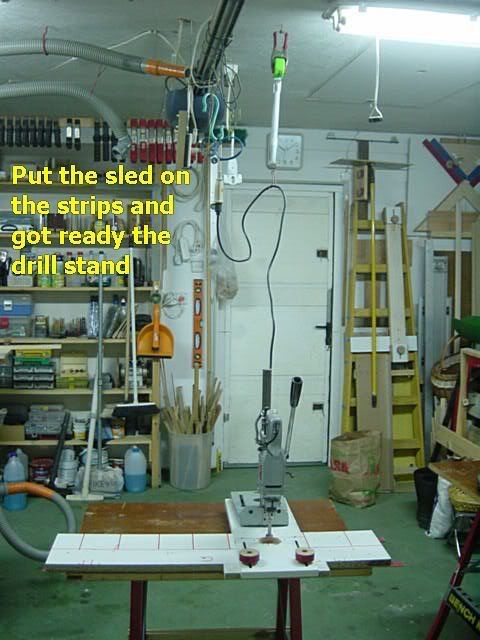

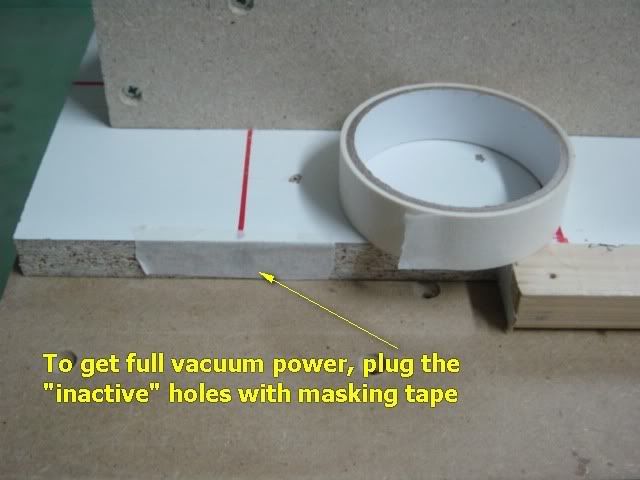

The Shop-vac is my converted home-vac that I used on "Minimum" power.

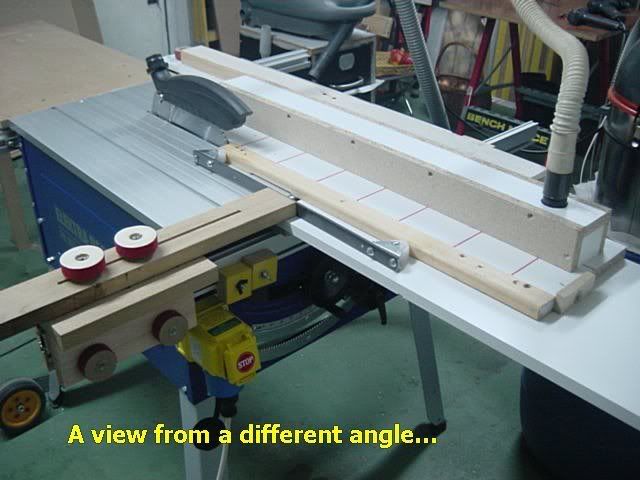

I strongly recommend to use a "Feather board" to hold the work and sled firmly to the fence before entering the blade...especially on long boards

You can add a push handle...I just use the "box" to push the sled.

Regards

niki

I would like to share with you an idea that was "sitting" in my head for long time and yesterday, I made it.

The title is "2 mm" (5/64") because I tested it by cutting 2mm strips but, it can be any thickness of strips....even less...

So...the sled is an 3/4" Melamine board 36" long and 8" wide but, you choose yours.

I drilled 3/8" "Vacuum holes" but first I drilled 1/4" as a pilot hole (easier to control the drill) and than went with the 3/8" drill bit to the end of the drill length

I drilled the holes at 4" intervals but I think that the more holes, the better (say, every 2½"~3") even though, I did not have any problems with the vacuum pressure.

I drilled 3/4" hole dia at the "end of the drill line"

The "Box" can be made of anything...I made it from pieces of chip-board and Melamine (that's what I found in the attic)

The Shop-vac is my converted home-vac that I used on "Minimum" power.

I strongly recommend to use a "Feather board" to hold the work and sled firmly to the fence before entering the blade...especially on long boards

You can add a push handle...I just use the "box" to push the sled.

Regards

niki

Comment