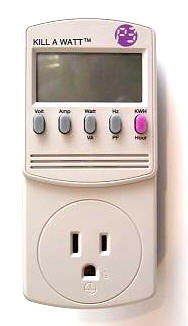

I was wondering if there is any standards that power tool manufactures use to rate power tools amperage? The reason I ask is I got one of those Kill A Watt devices that can measure such primarily to measure power used by all the various computers in the house.

So I figured I would try it out on my power tools to see what the results were. Here were my findings on amps used on various tools with no load after about 15 seconds from startup along with "rated" amps.

Pro Tech 10 CMS - 5.5 rated 15

Ryobi BT3100 TS - 6.8 rated 15

Craftsman RAS - 9.8 rated 11

Hitachi 12 CMS - 8.2 rated 15

Milwaukee drill - 2.5 rated 5.5

Rigid 2.5 HP vac - 7.2 rated 7.3

Interestingly my Craftsman RAS used the most idle amps and was rated lowest amperage of my saws I tested. I tried the RAS when crosscutting

a 1X6 board and it went up .2 amps. I also have to wonder why my two

CMS that are both rated at 15 amps had such a large difference in idle amperage. I know the Hitachi has a larger blade but I can't imagine that

would account for the 2.7 amps difference. I watched as I used a hole saw

for drilling with my Milwaukee Hole Shooter drill and the amperage draw went up to 5.0 amps which is close to it's rated amps. The Rigid 2.5 HP vac was right at rated amps and if put my hand over the end of the tube the amperage actually dropped to 5.5 amps.

Even though the Craftsman RAS is rated the lowest in amps of my saws my test shows it used the most idle amps by far and my experience is that it is easily my most powerful saw despite the amp ratings. It is however 25 years old and maybe back then they rated amps more realistically or to some standard no longer followed? I guess my point is that after reviewing results I don't really believe in the amps rating of various power tools is a reliable indicator of the performance of the tool. --- Steve

So I figured I would try it out on my power tools to see what the results were. Here were my findings on amps used on various tools with no load after about 15 seconds from startup along with "rated" amps.

Pro Tech 10 CMS - 5.5 rated 15

Ryobi BT3100 TS - 6.8 rated 15

Craftsman RAS - 9.8 rated 11

Hitachi 12 CMS - 8.2 rated 15

Milwaukee drill - 2.5 rated 5.5

Rigid 2.5 HP vac - 7.2 rated 7.3

Interestingly my Craftsman RAS used the most idle amps and was rated lowest amperage of my saws I tested. I tried the RAS when crosscutting

a 1X6 board and it went up .2 amps. I also have to wonder why my two

CMS that are both rated at 15 amps had such a large difference in idle amperage. I know the Hitachi has a larger blade but I can't imagine that

would account for the 2.7 amps difference. I watched as I used a hole saw

for drilling with my Milwaukee Hole Shooter drill and the amperage draw went up to 5.0 amps which is close to it's rated amps. The Rigid 2.5 HP vac was right at rated amps and if put my hand over the end of the tube the amperage actually dropped to 5.5 amps.

Even though the Craftsman RAS is rated the lowest in amps of my saws my test shows it used the most idle amps by far and my experience is that it is easily my most powerful saw despite the amp ratings. It is however 25 years old and maybe back then they rated amps more realistically or to some standard no longer followed? I guess my point is that after reviewing results I don't really believe in the amps rating of various power tools is a reliable indicator of the performance of the tool. --- Steve

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment