A friend wants to put a crown molding on a 'tray ceiling' (ie, the molding does not touch the ceiling in that area), so he needs a 'backer' from a 2x4 to be screwed to the wall, and then he'd attach the moulding to it.

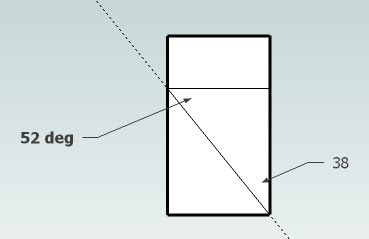

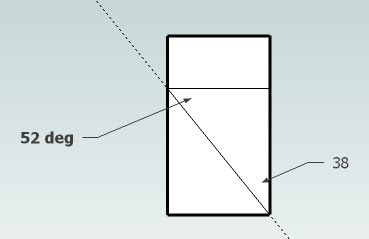

He needs me to cut the 2x4 at an angle of 38 degrees from the vertical, with the 2x4 on it's side :

My TS can handle upto 45deg from the vertical, so this is very possible. Problem is, I would need to raise the blade to a considerable height, and then run this 2x4 over it, and my hand is gonna be over the blade in close proximity. When I saw that I got a bit scared and came here for advise.

What is a safe way of cutting this? I have a couple of push sticks, but am unsure if they will have a good grip on this orientation. I also have the grripper, but am not sure if it will allow a 3 1/2" height.

Or am I being overly paranoid and should simply go thru the cut and be done with it?

(Of course, I'd need to add a sacrificial fence too to my rip-fence.)

He needs me to cut the 2x4 at an angle of 38 degrees from the vertical, with the 2x4 on it's side :

My TS can handle upto 45deg from the vertical, so this is very possible. Problem is, I would need to raise the blade to a considerable height, and then run this 2x4 over it, and my hand is gonna be over the blade in close proximity. When I saw that I got a bit scared and came here for advise.

What is a safe way of cutting this? I have a couple of push sticks, but am unsure if they will have a good grip on this orientation. I also have the grripper, but am not sure if it will allow a 3 1/2" height.

Or am I being overly paranoid and should simply go thru the cut and be done with it?

(Of course, I'd need to add a sacrificial fence too to my rip-fence.)

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment