Earl, are you using the guard? Right now I am on the fence (pun intended) on whether to keep my BT and get a Shark Guard or upgrade to this saw. Whatever direction I go, I want to start using a guard on my saw. The video online of this saw looks kind of goofy with the two part guard, but it might be something that is really useful, I don't know.

Bought a 21833

Collapse

This topic is closed.

X

X

-

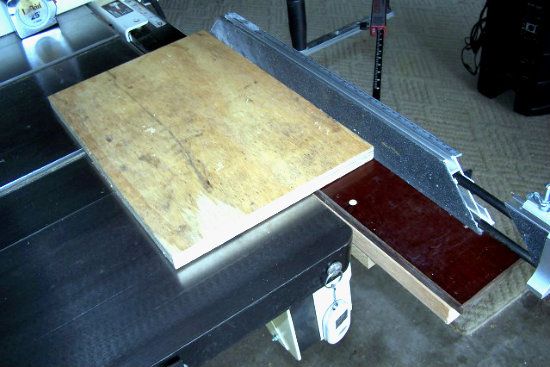

i think you'll find that, with the additional depth in front of th esaw blade, a larger sled can be accommodated for even more crosscut capacity. enjoy your new saw. properly cared for, it should provide you with years of trouble free service. just beware of that pitfall that bigger and better tools necessarily make one a better WW.I've not had any real time on the new saw yet, but one of the trigger points for me was 12" of table in front of the blade, versus 6" or so. That looks like a football field for squaring rough cut lumber. Time will tell.

By the way--every hardware bag had exactly everything listed, no spares but no shortages either!!

earlthere's a solution to every problem.......you just have to be willing to find it.Comment

-

Happiness is sort of like wetting your pants....everyone can see it, but only you can feel the warmth.

Comment

-

Yep--and that was a thought. My BT guard was getting a little sloppy side play, and on thin rips (straightlining for example) would skew to the thin side and grab the offcut. Started doing the math on a Shark Guard, likelihood of replacing the 1996 factory belts at $60 +/-, between those two i was halfway to new.Earl, are you using the guard? Right now I am on the fence (pun intended) on whether to keep my BT and get a Shark Guard or upgrade to this saw. Whatever direction I go, I want to start using a guard on my saw. The video online of this saw looks kind of goofy with the two part guard, but it might be something that is really useful, I don't know.

Not enough cutting to determine if dust collection will be adequate with that guard design--hard to believe it will be as good as the stock BT and definitely won't capture like one of Lee's guards!!

earlComment

-

Table saws are the center of most shops as far as equipment goes. I find it a very personal type of machine, as I've spent more time operating one than any other machine in the shop. Whenever I got another one...new or used, it was always a real event getting to know it.

I wish you good luck with your purchase, and hope you enjoy it safely.

.Comment

-

Progress...

Called on Monday morning and they agreed to send an extension table out, said it shouldn't take long since they ship from Chicago. He offered a few tips on aligning the fence--which i agreed to try before pursuing a replacement any further.

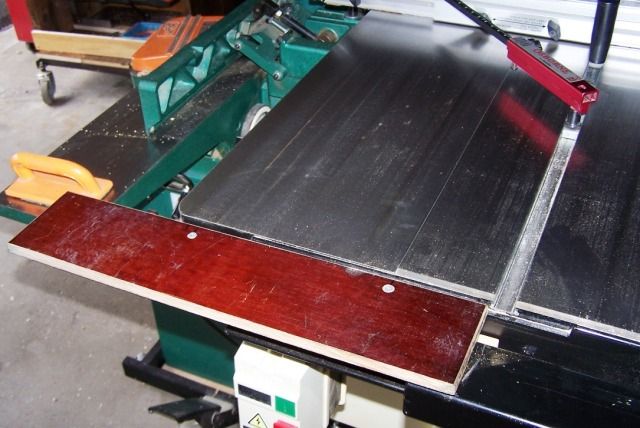

Got home late Tuesday night and the table had arrived--excellent. Put it on last night, stamped lip was dead flat, lined up really nicely. put the fence back on and it moved much more smoothly. Seems that by forcing the extension wing into compliance it threw the rail off just enough to bind. Only took a few minutes of adjusting the fence back (i'd tweaked a lot trying to get it right to start with!!) and was quickly parallel, perpindicular and square. Since they did not want the original wing back, and it was flat on top, i mounted it between the rails without attaching to the other wing. Lined up well and adds a ton of flat space.

Started cutting the pieces for mounting my dust collector on the wall. The included blade is not of great quality--but for cross-cutting 2 x 6 that will be buried in a box it was functional. Need to swap the Freud off my BT tonight to finish. Getting happier.Comment

-

I am enjoying this story, please keep the observations coming.

I don't see anybody wanting a unisaw to be a problem. I bought a BMW convertible that is not really necessary either. It's OK to buy what you want. But I think it's a little silly to pretend that lesser devices will do an inferior job. I can make about anything with my BT3100 that you can make with a unisaw. I have ripped 3 1/2 thick hardwood before with my BT3100. It takes a clean, sharp blade and a slow rate of feed but it can be done. I'd rather have a more powerfull saw occasionally but to argue I can't do something or my projects suffer because of my tools just doesn't seem correct at all to me. My skill will remain the primary limitation, not my tools. A BT3100 or a Craftsman table saw will do excellant work when the user is capable. It may be a little easier to get the same results with a Unisaw but the same result is available regardless.

The reason I find this interesting is I too am thinking. I do not use my BT3100 for crosscuts unless it is pretty small pieces. When I crosscut I use an Osborne gauge in a home-made miter slot table. Wider cross cuts are made with a CMS, radial arm or now my track saw. I have to mess with the setup on the table to get it accurate when using the Oborne gauge. Milled slots in a metal table top would be nice.

JimComment

-

FWIW, I have professionally used cabinet saws on a daily basis over at least the last fifty years. Saws used include the Unisaw (specifically the General, an upgraded enhancement of the Unisaw) and sliding table saws like the Felder (an industrial saw several steps up from the Unisaw) as well as a range of smaller saws, including Craftsman and, of course, the BT3X saw. In my opinion, each has their place. The primary limitation of the cabinet saws for smaller shops is weight and size - but as you note, they do a great job at compensating for less experience and skill. As others have noted, for one who doesn't really understand how to use a table saw and might only use a table saw five or six days a week, the cabinet saws are very forgiving and can compensate to a degree for limited experience. Saws like the BT3X, while capable of greater precision, do require somewhat more skill and experience to get results comparable to a cabinet saw, as they are not as forgiving of errors. In addition, the smaller saws like the BT3X weigh less and take up less room, so they are easier to move around in a small shop. As I have gotten older and don't have the strength I did as a young man of 50 years old :-; I find the lighter weight to be a huge advantange when moving the saw.But to sell off a Unisaw to stick to a smaller less utilitarian saw to me sounds either because it wasn't put together properly or simply haven't developed a need/skills for a better saw as of yet and may never develope the necessary skills needed to do larger more complex work.Last edited by woodturner; 01-31-2013, 08:35 PM.--------------------------------------------------

Electrical Engineer by day, Woodworker by nightComment

-

By those statements, you don't have a clear understanding concerning the use of a tablesaw. Your perspective of smaller saws is understandable, as amateurs and hobbyists like yourself, may only need one on an occasional basis. They are a fine saw for what they are designed for, and if you find one "Not as forgiving of errors and it takes more skill and experience to get results comparable to a cabinet saw", then you should work on your operating technique.

For those skilled with tablesaws in general, can achieve comparable results. And, for those like myself that use tablesaws daily, at times 5-6 days a week, will likely find that the smaller saws won't hold up to that heavy use for 20-30+ years like a well set up Unisaw or Powermatic.

.Comment

-

I have to disagree on the mobility issue. Ii just came in from doing a little work in the shop, and the new saw probably weighs 3 times my BT3000. I can move it with one hand then set it gently on its legs. Lifting onto the wheels requires not much more effort than pressing the brake pedal in my car. Yes, i could have (and often swore i would) replaced the lift mechanism on the BT--just never got a round tuit!!

Yep, it's bigger. Like working on a football field. But after i got my cuts done tonight, i popped off the blade guard, lowered the the riving knife, threw a 30" square sheet of cardboard on the top and started assembling the torsion boxes for mounting my DC on the wall. In 17 years i'd only removed the guard on the BT 2 or 3 times. Great system when it was new, along with the riving knife Ryobi included--quicker and easier system today. Guys like Lee Styron creating the Shark Guard led the way for that sort of convenience becoming "stock" and probably did more to advance safety (by making it easy to REPLACE the guard after removal) than any hot-dog-saving device inventor could dream of. (that opinion may not be shared by the managament, but that's my story and i'm sticking to it.)

Anyway, still got some habits to break. Like JimD, most of my cross-cutting has been on my RAS. Last night i was cross-cutting on the table and trying to support 6' of 2 x 6 hanging off the left, thinking i should have just stuck with the RAS. Then 4' was easier. Then i realized that i had a vacant drag strip on the right side...and a miter slot on that side too...DOH!!

earlComment

-

I am not speaking for the rest of the management, and I think Lee is much too humble of a guy to harbor such thoughts however I agree with your assessment.Guys like Lee Styron creating the Shark Guard led the way for that sort of convenience becoming "stock" and probably did more to advance safety (by making it easy to REPLACE the guard after removal) than any hot-dog-saving device inventor could dream of. (that opinion may not be shared by the managament, but that's my story and i'm sticking to it.)

earlDonate to my Tour de Cure

marK in WA and Ryobi Fanatic Association State President ©

Head servant of the forum

©

Comment

-

I wasn't clear in my post - I meant moving the saw between shops and locations, loading and unloading it in the truck. I agree that mobile stands make it easy to move tools, including saws, around within the shop.I have to disagree on the mobility issue. Ii just came in from doing a little work in the shop, and the new saw probably weighs 3 times my BT3000. I can move it with one hand then set it gently on its legs. Lifting onto the wheels requires not much more effort than pressing the brake pedal in my car.

My situation may be different, as I work in different shops. One is a reasonable size commercial shop, an old factory building I share with other woodworking companies, and we do share and use industrial tools like the General in that shop. These tools remain in place and are not even on mobile stands. In the other shop, quarters are tight as it's essentially the size of a one car garage, and we pretty much have to move each tool out from storage to use it, due to the space limitations. In this shop, I find the BT3X invaluable. When we travel to a client site to work on-site, I take the BT3X, not the General. That situation is really what prompted my comment, the need to move several shop power tools to a client site for particular kinds of work.--------------------------------------------------

Electrical Engineer by day, Woodworker by nightComment

-

To me the frustrating part of the BT3100 are the need to clean the lift mechanism (or it won't work), the need for a clean and sharp blade (or it will bog down in thick wood), and the lack of miter slots in a normal sense. None of this prevents good work. It just makes it more take a bit more time/effort. I wouldn't see any reasonable person using it commercially unless the size and weight was a big advantage. For my home shop where it doesn't get used even every week, the limitations are not so huge. But they may be enough for me to eventually move to "the dark side".

I really like my track saw especially for mobile use. I'd hate to give up my table saw but if I need to make some shelves or even a cabinet for my kids houses, I can see doing it with a CMS and the track saw. But maybe I will get a "real table saw" and convert the BT3100 back to mobile duty - which is it's strength anyway.

JimComment

-

On my 21833, I've installed the aux. miter slot accessory (in the open area to the left of the table/blade). I often use the small miter fence that fits the router table (I removed the circular retaining disc at the end). I also installed a small sacrificial wood fence on this.

When the 21833 is locked into the transport position, you can easily blow out the lift/rotate mechanism with a blow gun and a high pressure air line.Comment

-

are you referring to the 21833 or the 21829?On my 21833, I've installed the aux. miter slot accessory (in the open area to the left of the table/blade). I often use the small miter fence that fits the router table (I removed the circular retaining disc at the end). I also installed a small sacrificial wood fence on this.

When the 21833 is locked into the transport position, you can easily blow out the lift/rotate mechanism with a blow gun and a high pressure air line.

there's a solution to every problem.......you just have to be willing to find it.Comment

Footer Ad

Collapse

Black wallnut

Black wallnut

Comment