I am trying to find out what switch I need for a 240v three speed electric motor. I don't have the motor yet, but it will be a scavenged AC blower motor. I would like to be able to switch between the speeds if possible, but when I search for a switch online I don't come up with many viable options? I am thinking I need a 2 pole, 3 way rotary switch. I want to make sure that the windings are not energized at all, i.e. no 120v is present to prevent risk of shock. Can anyone enlighten me? Thanks in advance.

What kind of switch do I need?

Collapse

This topic is closed.

X

X

-

You might wait until you get the motor to see if you need a switch. I was given a 110v AC fan motor and based on the wiring diagram on the motor, I was able to work out a switch for 3 speeds.

Now, 240v might be a lot different.

Lago -

Thank you Lago.

I am almost certain that at its most basic, the 220v AC blower motor will require a selector switch of some sort unless I just wire it for single speed. Typically they are wired with a relay and dip switches or discrete electronics on a board. Anyone else have any ideas?I think in straight lines, but dream in curves

Comment

-

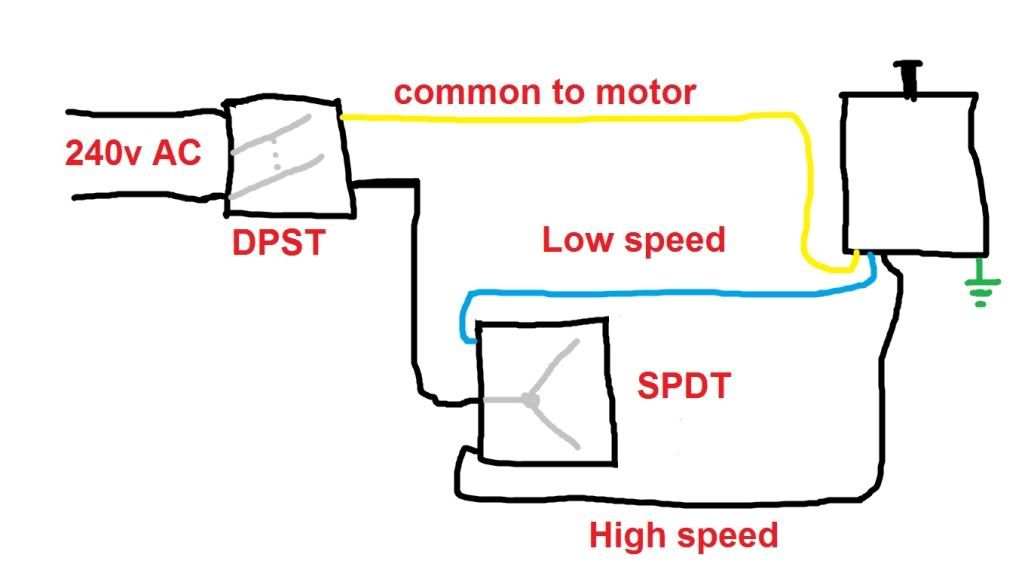

If it's like the last 110v fan motor I worked with it'll have a winding for each speed with one common lead. Not sure if 220 motors are the same. Here's a diagram from a 220 fan motor. Looks like a single pole 3 throw switch to change speeds.

Last edited by BobSch; 04-21-2012, 10:08 AM.Bob

Last edited by BobSch; 04-21-2012, 10:08 AM.Bob

Bad decisions make good stories.👍 1Comment

-

Thanks guys. Looks good Bob. I was trying to find a solution that switched all power going to the motor, I wasn't in love with the idea of leaving 120 in the motor lest someone work on it or service it while hot... I don't even think NEC requires switching both sides inputs on 220, but I'd prefer it. I guess I could always use two switches, on spst on the "common" and then a sp three throw...I think in straight lines, but dream in curves

Comment

-

Id wait to see if when you get it in your possesion if it cant be wired for 120v. Alot of them can in fact some of them are set for 120v and only the compressor runs on 240v. If your getting a motor from a self contained unit that is.

If not, what kind of amp draw are you expecting? As long as its not too high, you could probably just pick up a fused disconnect that will kill power to the whole motor (both L1 and L2) and just control the speed control leg (probably L2) with a 3 position toggle. Id look for one that doesnt have an off position. I know my local Ace hardware has one thats good for 15 amps, in that case i would use 10 amp fuses in the diconnect so they fail before the switch gets smoked.

Hope that helps. Sounds like a convultued thingamabob i would build.Comment

-

Unless you want an expensive drum style switch you'll need two switches, one SPST for on/off that switches both legs and another SP3T switch for the speed.Opportunity is missed by most people because it is dressed in overalls and looks like work. - Thomas Edison👍 1Comment

-

:O Thanks U.C. - it is a thingamabob and you did build one in the past

To clarify Tom, are you saying get a spdt so that both l1 and l2 get switched off? I figured there was an off on the sp3t that would accomplish the same in conjuction with a spst on the common.I think in straight lines, but dream in curves

Comment

-

I meant an DPST when I wrote SPST.

The SP3T is switching windings in the motor and I would not leave one leg hot. I guess you could use a DP4T and jumper all but one terminal on one side/leg.

Remember there is no common on 240v.Opportunity is missed by most people because it is dressed in overalls and looks like work. - Thomas EdisonComment

-

If you don't want any terminals hot then you should use a main power switch DPDT to disconnect both L1 and L2 from the fan.

if you want to select speeds then use a rotary SP3T switch to connect L2 to hi, med or low terminals.

An option to the SP3t rotary switch would be a three position toggle DPDT ON-ON-ON switch which is not real common but can be wired to select three inputs to one common terminal. They're kind of hard to find - but work like this:

in the up position the center terminals are connected to the bottom terminals for both poles.

in the down position the center terminals are connected to the top terminals for both poles

in the center position one pole is connected center to top and the other pole is connected center to bottom.

This can be wired as a SP3T switch with just a bit of imagination. Loring in Katy, TX USA

Loring in Katy, TX USA

If your only tool is a hammer, you tend to treat all problems as if they were nails.

BT3 FAQ - https://www.sawdustzone.org/forum/di...sked-questionsComment

-

Well I ended up with a beaut. of a blower motor assembly!

2006 3 ton from a carrier in very nice shape. Its a two speed and very quiet in operation. 2.6a at 240 so I guess I should look for a 10a dpst switch for the power lines and maybe a spdt with center off to select between the speeds.

What do you think?

Last edited by chopnhack; 04-25-2012, 09:47 PM.I think in straight lines, but dream in curves

Last edited by chopnhack; 04-25-2012, 09:47 PM.I think in straight lines, but dream in curves

Comment

-

make sure your switches are motor rated, not lighting rated.

and get a SPDT On-none-on (no center off. WHy would you want another off position when you have the main DPST switch.) Loring in Katy, TX USA

Loring in Katy, TX USA

If your only tool is a hammer, you tend to treat all problems as if they were nails.

BT3 FAQ - https://www.sawdustzone.org/forum/di...sked-questionsComment

-

Thanks Loring. They are rated up to 1.5hp. As for the on off on, that was all I found on my initial search, thanks for the tip, I will look some more! My interest is in now cobbling together a timer. I seem to remember from another lifetime using a 555 ic as a kid do something of that order...I think in straight lines, but dream in curves

Comment

Footer Ad

Collapse

Comment