I like your whims and that one looks great.

Tool Chests Revisited

Collapse

This topic is closed.

X

X

-

Hopefully that's it. In reality, probably half of them don't use the tools they keep in them. There's been a real variety of intended uses. From drafting tools to jewelry.

As for finishes, I did two in just an oiled finish, and have used lacquer, oil based polyurethane, and water based polyurethane. I've had no calls for finish problems (yet).

.Comment

-

nice! too good looking to be in the shop.

if you were to build one on wheels, how would you lock the drawers from opening?_________________________

omarComment

-

online at http://www.theFrankes.com

while ( !( succeed = try() ) ) ;

"Life is short, Art long, Occasion sudden and dangerous, Experience deceitful, and Judgment difficult." -HippocratesComment

-

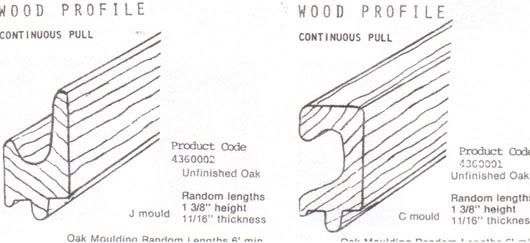

Thanks for the compliment. The drawer fronts can be done in solid wood and a "finger pull" router bit can be used for the "integrated detail":

.

.

Or, to have some continuity of grain for the drawer fronts, plywood can be used and an add on profile (available in random lengths, mostly in Red Oak) used on the top or bottom edge. To use these, the lip in the front and the spline can be cut off. The profile can then be glued directly and be "flush" to the front.

.

.

I've had many PM's for details, and I will assemble a tutorial for this project in the "Project Related Discussions" when completed.

Edit: I forgot to address the drawer construction. The drawers are done with rabbeted sides to accept the fronts and backs. The sides and front are grooved to accept the bottom. The back is cut short to accept a 1/4" hardwood plywood bottom. The drawer front is a separate piece.

.Last edited by cabinetman; 05-19-2008, 11:25 AM.Comment

-

Ah yes, I'm familiar with this technique. My shop cabinets are built this way. Unfortunately my plywood drawer fronts don't stay put very well. I'm pretty sure it's operator error...Edit: I forgot to address the drawer construction. The drawers are done with rabbeted sides to accept the fronts and backs. The sides and front are grooved to accept the bottom. The back is cut short to accept a 1/4" hardwood plywood bottom. The drawer front is a separate piece.

JRJRComment

-

Footer Ad

Collapse

Comment