Hi all, thought I'd register since I now own a BT3x. I'm fairly new to woodworking (still learning) but I love fixing/building things and have done it as long as I can remember but mostly cars related. I started with a cheap $100 Craftsman TS back in 2008 when I decided I wanted to do try 'home improvement'. I think it was another excuse to buy more tools but I digress. After putting in laminate flooring (a passable job at best, thank god for base boards to hide the imperfect ends) in one of the bedrooms and getting several kickbacks  from the saw (before I new what a KB was) in the process I put it away and got busy with life and things. Until recently when I dusted off the old TS, put in a new Freud 50-tooth blade, built a sled for it and squared it up (it was so out of square) - all thanks to YouTube. Then, after building a few garage organization items I realized the 10" cutting capacity to the right of the blade is not going to cut it. the fence was a bit tough to setup too. So after some research I almost bought the Bosch but then I kept coming across something called the Ryobi BT3x. Some more research lead to this forum and the cult following. A month or so later one came up on Craigslist for $200, I showed up, made sure the motor turned, handed the money over and brought it home. Just about every alignment was off and man there are so many on this saw. I went ahead and ordered the accessory kit for $100 and also a few old replacement parts and a riving knife (didn't come with one). At this point the saw was cutting great except the SMT. After spending hours over the course of a few evenings I realized the SMT fencehold down plastic bracket has a crack and it moves even after being cranked down. So ordered a new one but the delivery took a while so I ended up building a sled and I like it much better. In fact, I'd like to buy another extension piece (where you mount the router) and get rid of the SMT altogether. Finally I added a shelf at the bottom of the stand and made a fold down out-feed table with the help of T-nuts sourced from t-nuts.com (btw Robert is great to deal with, he gave me lots of pointers for aligning the SMT).

from the saw (before I new what a KB was) in the process I put it away and got busy with life and things. Until recently when I dusted off the old TS, put in a new Freud 50-tooth blade, built a sled for it and squared it up (it was so out of square) - all thanks to YouTube. Then, after building a few garage organization items I realized the 10" cutting capacity to the right of the blade is not going to cut it. the fence was a bit tough to setup too. So after some research I almost bought the Bosch but then I kept coming across something called the Ryobi BT3x. Some more research lead to this forum and the cult following. A month or so later one came up on Craigslist for $200, I showed up, made sure the motor turned, handed the money over and brought it home. Just about every alignment was off and man there are so many on this saw. I went ahead and ordered the accessory kit for $100 and also a few old replacement parts and a riving knife (didn't come with one). At this point the saw was cutting great except the SMT. After spending hours over the course of a few evenings I realized the SMT fencehold down plastic bracket has a crack and it moves even after being cranked down. So ordered a new one but the delivery took a while so I ended up building a sled and I like it much better. In fact, I'd like to buy another extension piece (where you mount the router) and get rid of the SMT altogether. Finally I added a shelf at the bottom of the stand and made a fold down out-feed table with the help of T-nuts sourced from t-nuts.com (btw Robert is great to deal with, he gave me lots of pointers for aligning the SMT).

Sled:

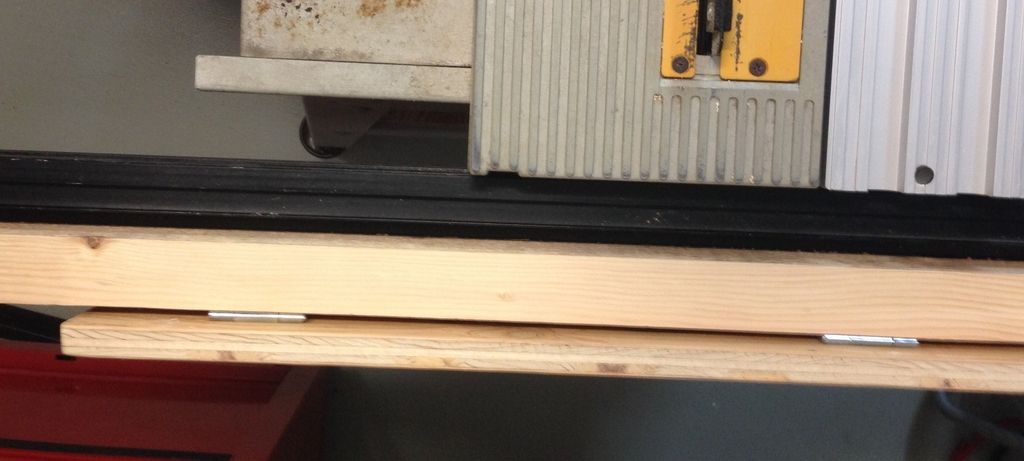

Cuts square enough for me:

Small fold-down out-feed table:

The saw stows away under the workbench (I have it on furniture moving pads so I just push and slide it where I need it) since I park two cars in the garage. The dust is a bigger pain to have to clean up each time I cut anything.

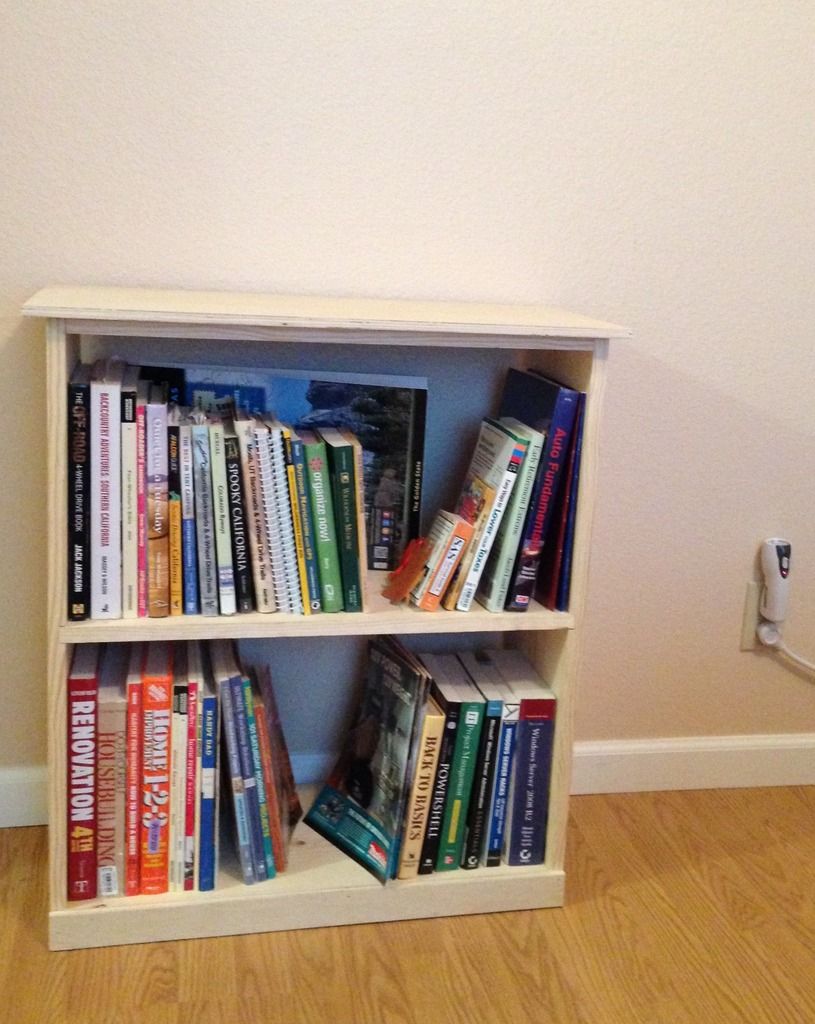

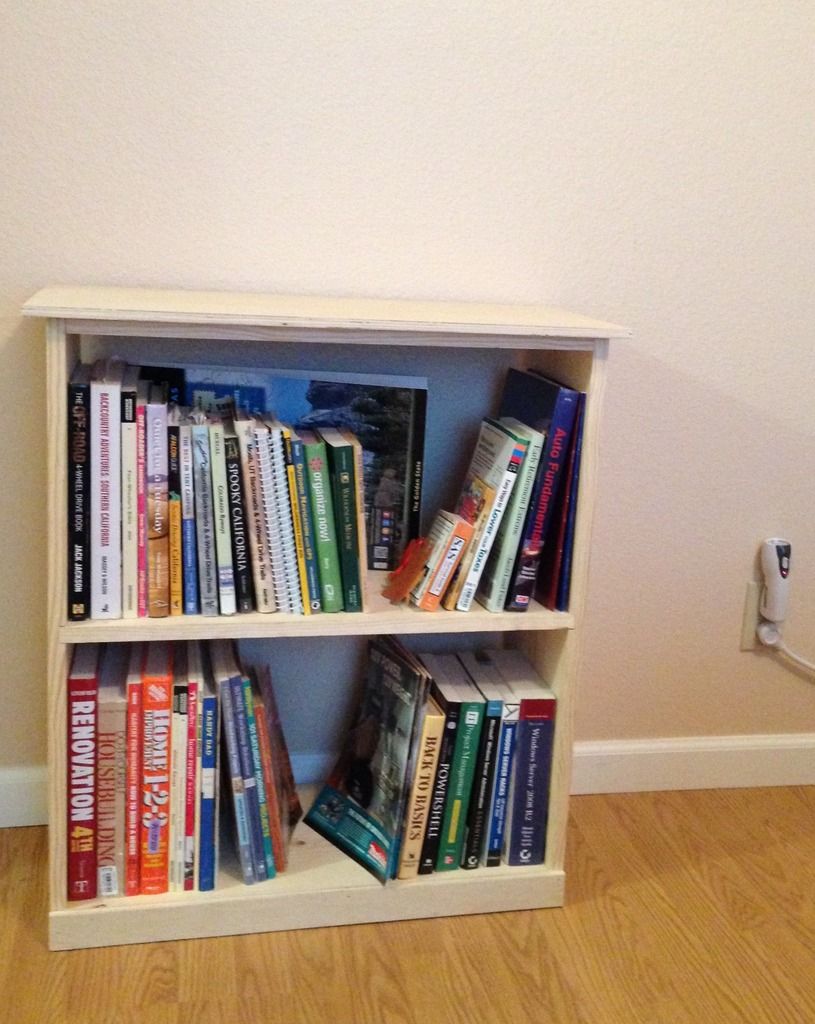

Here's the only indoor (non-garage) project I've built with it so far, made out of pine and birch plywood.

I'm open to any thoughts, recommendations, jigs, mods, must-dos related to the saw. I'm already thinking about buying a 6" dado blade set for it. I'm hoping once it's perfectly setup I wouldn't have to tinker with it as much as I've had to so I can concentrate on make things with it rather than for it

from the saw (before I new what a KB was) in the process I put it away and got busy with life and things. Until recently when I dusted off the old TS, put in a new Freud 50-tooth blade, built a sled for it and squared it up (it was so out of square) - all thanks to YouTube. Then, after building a few garage organization items I realized the 10" cutting capacity to the right of the blade is not going to cut it. the fence was a bit tough to setup too. So after some research I almost bought the Bosch but then I kept coming across something called the Ryobi BT3x. Some more research lead to this forum and the cult following. A month or so later one came up on Craigslist for $200, I showed up, made sure the motor turned, handed the money over and brought it home. Just about every alignment was off and man there are so many on this saw. I went ahead and ordered the accessory kit for $100 and also a few old replacement parts and a riving knife (didn't come with one). At this point the saw was cutting great except the SMT. After spending hours over the course of a few evenings I realized the SMT fencehold down plastic bracket has a crack and it moves even after being cranked down. So ordered a new one but the delivery took a while so I ended up building a sled and I like it much better. In fact, I'd like to buy another extension piece (where you mount the router) and get rid of the SMT altogether. Finally I added a shelf at the bottom of the stand and made a fold down out-feed table with the help of T-nuts sourced from t-nuts.com (btw Robert is great to deal with, he gave me lots of pointers for aligning the SMT).

from the saw (before I new what a KB was) in the process I put it away and got busy with life and things. Until recently when I dusted off the old TS, put in a new Freud 50-tooth blade, built a sled for it and squared it up (it was so out of square) - all thanks to YouTube. Then, after building a few garage organization items I realized the 10" cutting capacity to the right of the blade is not going to cut it. the fence was a bit tough to setup too. So after some research I almost bought the Bosch but then I kept coming across something called the Ryobi BT3x. Some more research lead to this forum and the cult following. A month or so later one came up on Craigslist for $200, I showed up, made sure the motor turned, handed the money over and brought it home. Just about every alignment was off and man there are so many on this saw. I went ahead and ordered the accessory kit for $100 and also a few old replacement parts and a riving knife (didn't come with one). At this point the saw was cutting great except the SMT. After spending hours over the course of a few evenings I realized the SMT fencehold down plastic bracket has a crack and it moves even after being cranked down. So ordered a new one but the delivery took a while so I ended up building a sled and I like it much better. In fact, I'd like to buy another extension piece (where you mount the router) and get rid of the SMT altogether. Finally I added a shelf at the bottom of the stand and made a fold down out-feed table with the help of T-nuts sourced from t-nuts.com (btw Robert is great to deal with, he gave me lots of pointers for aligning the SMT).

Sled:

Cuts square enough for me:

Small fold-down out-feed table:

The saw stows away under the workbench (I have it on furniture moving pads so I just push and slide it where I need it) since I park two cars in the garage. The dust is a bigger pain to have to clean up each time I cut anything.

Here's the only indoor (non-garage) project I've built with it so far, made out of pine and birch plywood.

I'm open to any thoughts, recommendations, jigs, mods, must-dos related to the saw. I'm already thinking about buying a 6" dado blade set for it. I'm hoping once it's perfectly setup I wouldn't have to tinker with it as much as I've had to so I can concentrate on make things with it rather than for it

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment