Does anyone have any pictures of how to attach a homemade table to the rails of a BT3100? I am having trouble figuring out a way to attach a table of two layers of 3/4 MDF. Thanks

attaching table

Collapse

This topic is closed.

X

X

-

Sorry, I don't seem to have any pictures at hand. But the method is fairly simple, once you have (or make) a few parts.

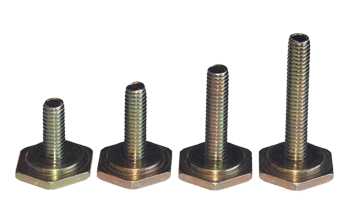

The easiest approach is to use some t-bolts like these:

They slide into the slots on the inner sides of the BT3 rails. Then, cut some slots into some aluminum angle to slip over these bolts, leaving the other flat surface on top, facing inboard. Attach your mdf table top to this.

The advantage to doing it this way is that just by loosening the nuts on the t-bolts, you can lift the table out.

Regards,

TomComment

-

I plan on doing this to build a flat surface that attaches to an extra set of rails (wide table). You need to support the extra set of rails because they will sag at the joint. Also, the combination of a heavy piece of stock and the table might cause the whole thing to tip.

I was thinking about using wood instead of aluminum but a piece of angle would be easier and less time-consuming than building up something. Tom, how did you cut the slots? Can it be done with a router turned down to its slowest speed and a HSS bit or do you need proper metal cutting equipment?Comment

-

Those t-bolts, and the other t-nuts and such found at the site Tom linked, slide into the slots on the rails and fences of the BT. Best thing since sliced bread.Originally posted by jackellisTom, how did you cut the slots? Can it be done with a router turned down to its slowest speed and a HSS bit or do you need proper metal cutting equipment?

JRJRComment

-

Just get some aluminum angle and attach it to the bottom of the edge of your table. Then drill holes in it to line up with the rear t-bolt slot on the rails...some nuts or knobs for the t-bolts and Bob's your uncle.

Take a good look around Jeff's site. I would recommend the Shark Levers with T-nuts for this instead of t-nuts with knobs. Easier to tighten/loosen.Brian

Welcome to the school of life

Welcome to the school of life

Where corporal punishment is alive and well.Comment

-

I just built one and it was easy, and cheap (about $20)

Used a 3/4" - 2'x4' melamine board from HD, a few scraps of 2”aluminum bar and 2” angle.

Used the bar to sit in the same channel on the rear rail at the router table section. Used a cut up piece of board to space the alum bar 3/4 under the bottom of the table top. For the front I used a cut down piece of angle to sit in the track that a t-nut would go into. Spaced that down with some more cut up board pieces. It’s a little flimsy going in and out, but once in it's solid. Seems to work well, and looks not bad. I should take a pic.

(btw, the left side is the front of the saw)Last edited by dsellinger; 07-12-2006, 01:11 PM.Comment

-

I used a DP to drill the 5/16" holes at the midpoint of one side of the Al angle, then used either a hacksaw or miter saw to cut the slot to the hole.Originally posted by jackellisTom, how did you cut the slots?

By drilling the holes at the same vertical position, you get the Al angle sitting at the same height. Then, you can shim between the angle and your table to set the table height. That way, when you pop the table in and out, it registers to the same height -- no tweaking.

Regards,

TomComment

-

I made plywood brackets. Thread here:

http://www.bt3central.com/showthread.php?t=19316

Scroll down to second or third message for pics.Comment

-

-

Oh, I get it -- no bolting required, right? Your al angle is just sitting down in the channel, with a reasonably snug fit? That's pretty slick!Originally posted by dsellingerPics from lunch

Regards,

TomComment

-

-

Thanks to all!

Thank you to everyone for you thoughtful responses.

And to Pappy I have to fess up and admit that I took the easy way out. I only had a quick minute at the computer and did not have time to do a search of the archives. I went for the easy way out by posting a repeat question. So I apologize to all for the redundency.

My concern was that in all of my designs I couldn't figure out a system that didn't leave me shimming the top through trial and error. I was hoping that someone had come up with a solution that involved some exact measurements and left the table attached securely with no play.

dsellinger, Thanks for taking the time to post pics. I like y our method in that I could leave the AI corner bracket a little on the long side and trim until getting the exact fit. But does this leave the table with a lot of play? Given that there has to be enough room to slide it out and back in. Or did you make it permenent?

The other option might be to use Tom's t-nut/bolt solution and take the time to carefully trim the holes until getting an exact fit on the top. Then the table wouldn't require shims.Comment

-

There could be some play if you were pulling up on the table.. But only about 1/16 on the front and about 1/4 at the rear. Gravity seems to be doing a good job for me so far.

You don't need to do things by trial and error either, just measure with a square or some calipers from the fixed table top to the bottom of the channel/groove you will be using.Comment

Footer Ad

Collapse

Comment