Good day

I made this table for different purpose but, I will not tell you which one because you will laugh at me...

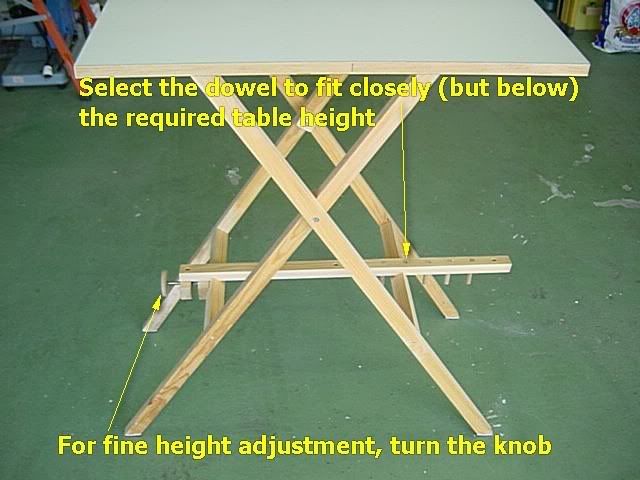

But, while working on it in the garage, I thought that I can use it also as an adjustable height table for the Drill press, table saw, router table and alike to support long boards.

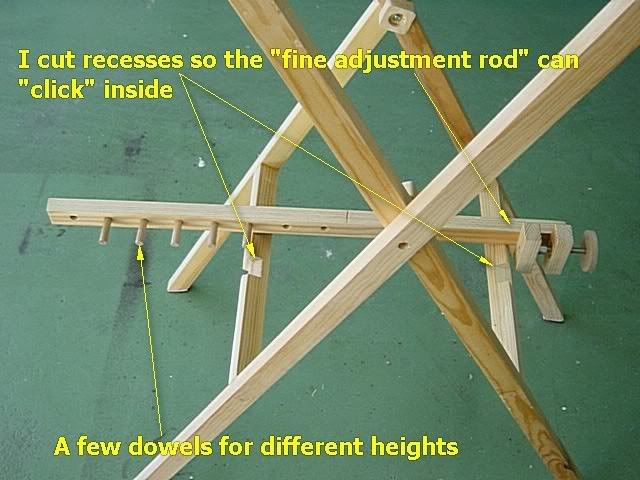

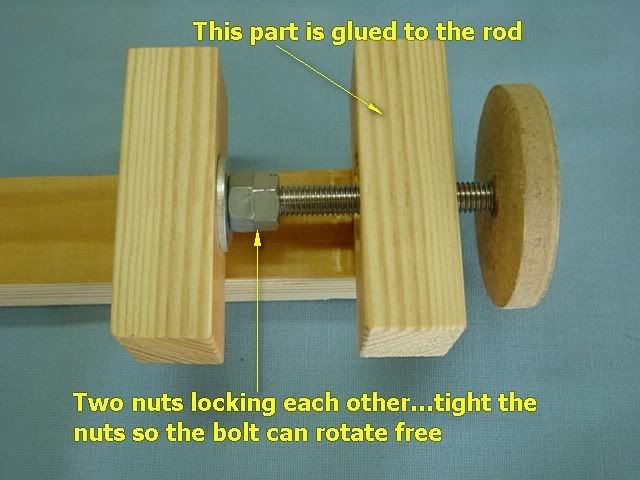

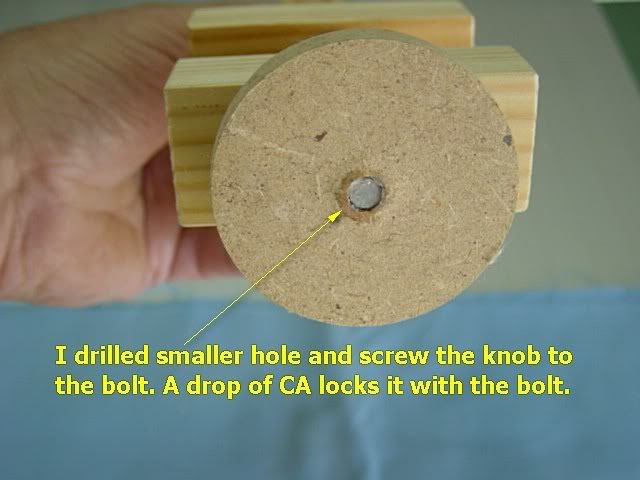

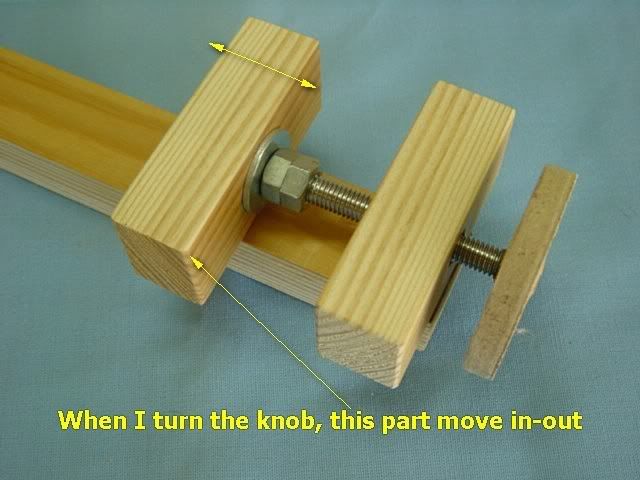

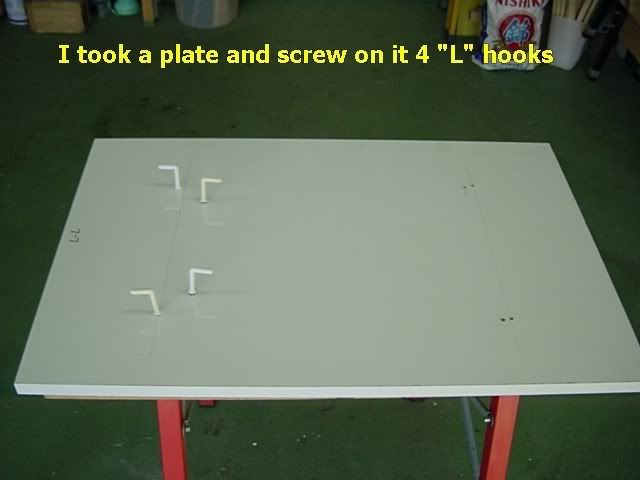

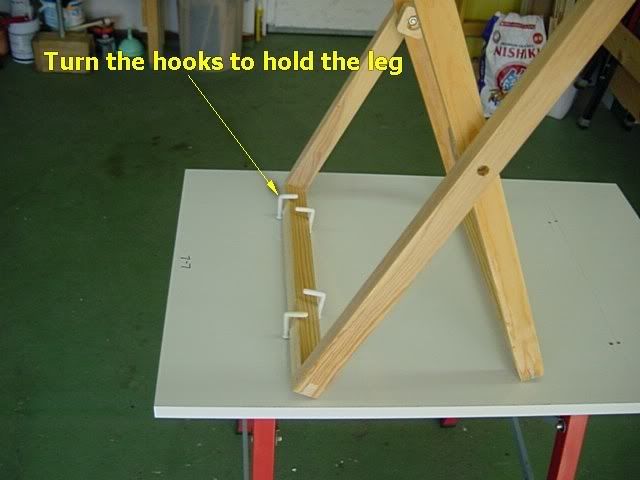

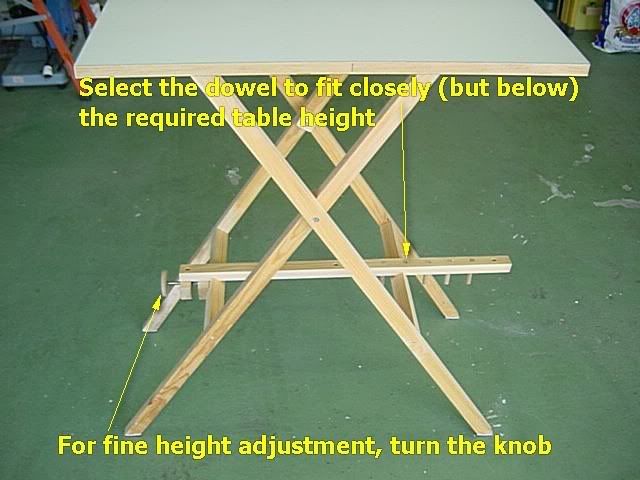

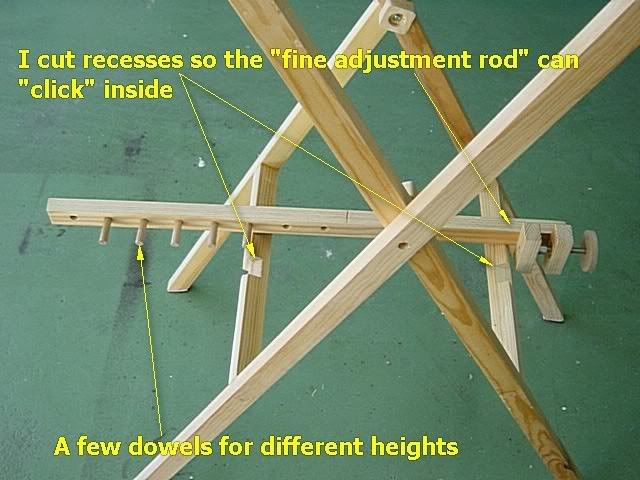

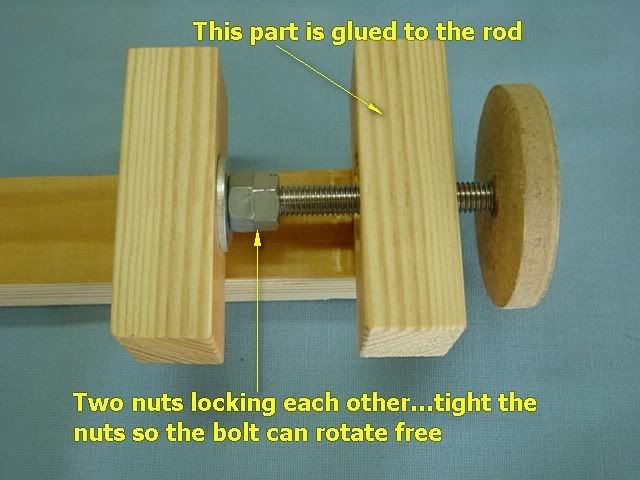

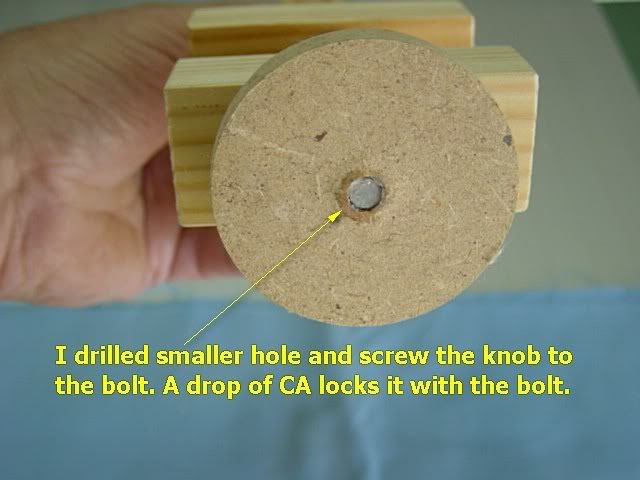

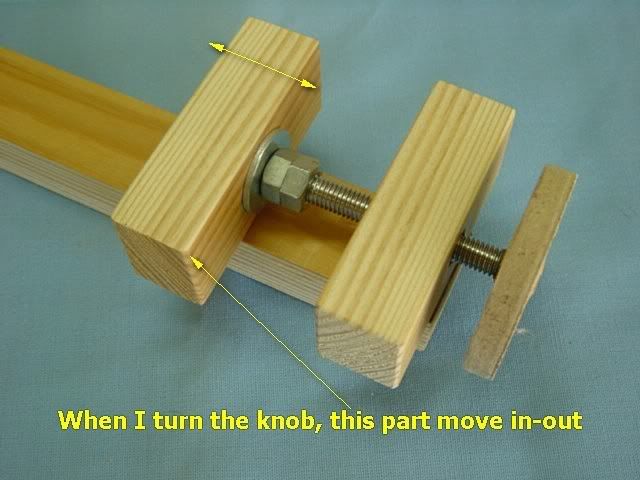

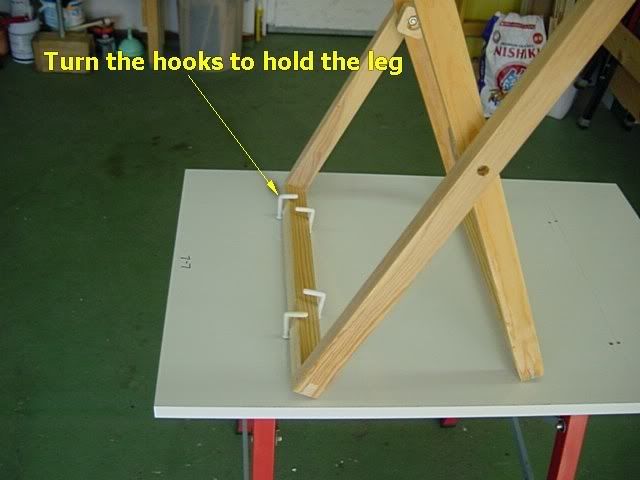

The base is two frames, M&T (made with the "rolling tenon jig" on the table saw), connected with bolts as an X...the top can be any plywood, melamine or whatever.

If I would make it for the shop, I would make it from more "massive" wood, say 2" x 4", wider footprint and maybe pipe clamp for height adjustment so, I can use it also as a low (or high) assembly table

I did not have intention to post it but then, I thought, maybe it will give somebody some ideas so, here it is.

Regards

niki

I made this table for different purpose but, I will not tell you which one because you will laugh at me...

But, while working on it in the garage, I thought that I can use it also as an adjustable height table for the Drill press, table saw, router table and alike to support long boards.

The base is two frames, M&T (made with the "rolling tenon jig" on the table saw), connected with bolts as an X...the top can be any plywood, melamine or whatever.

If I would make it for the shop, I would make it from more "massive" wood, say 2" x 4", wider footprint and maybe pipe clamp for height adjustment so, I can use it also as a low (or high) assembly table

I did not have intention to post it but then, I thought, maybe it will give somebody some ideas so, here it is.

Regards

niki

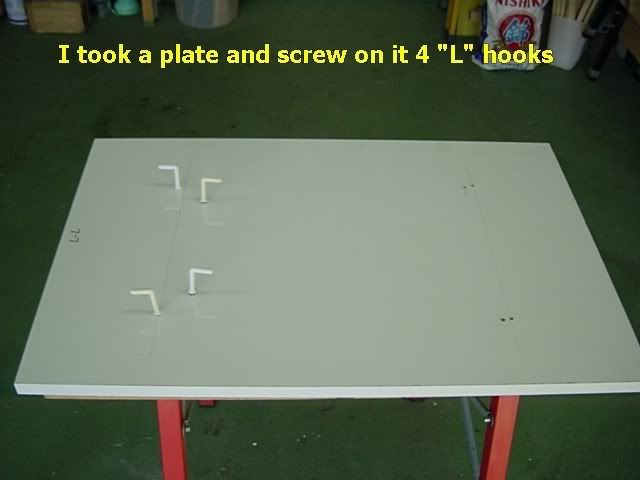

So, when I clean the tops in the bathroom, toilet, cabinets and shelves, I have to remove all the "art collections" and put them on the floor or another furniture...

So, when I clean the tops in the bathroom, toilet, cabinets and shelves, I have to remove all the "art collections" and put them on the floor or another furniture...

Comment