Good day

Today, I was working on the router table fence, the "Fence/Bit" precision distance system and the "Fence stops" precision positioning system.

I took some 3 Tons of pics but I have to "Delete", "Sharpen", "Add Text" etc and it will take some time to post.

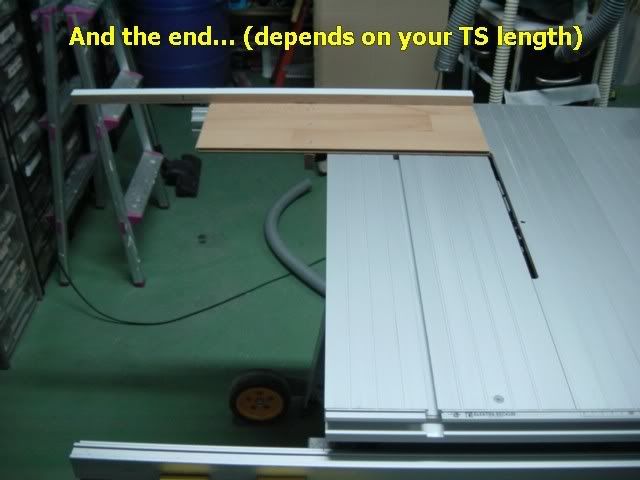

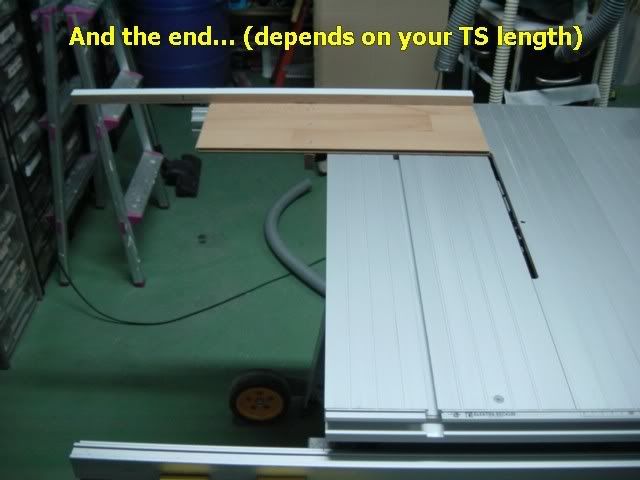

In between, I needed a sled to cut small (and not so small) pieces so I made one in 15~20 minutes from the "Floor Panels" left-over that I used for the router table.

I called it "All seasons sled" because temp and humidity changes are not effecting the sled runners that usually are expanding and contracting with humidity changes.

The sled is always tight, without any "Side play" and can be "re-adjusted" in seconds.

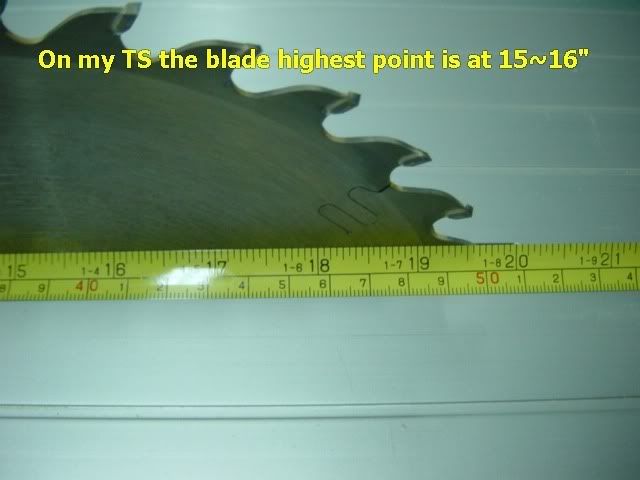

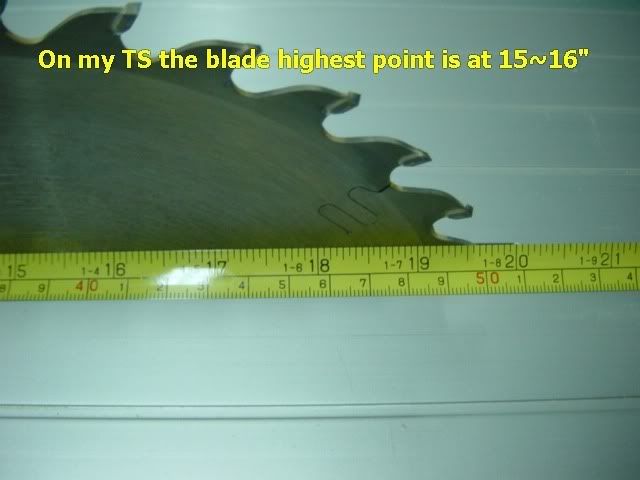

Because of the construction method, everything is very square to the blade and no need of "Two cut test" or "Five cut test"...it's dead 90°...as long as the blade is parallel to the miter slot and your triangle is accurate...

And last, it's sliding, actually half rolling, and is very, very easy to push-pull.

Many variations can be done on this sled and I leave it to your imagination (I have a few ideas).

Sorry but I did not take any pics of the WIP so if you have any questions, I'm here...

Regards

niki

Today, I was working on the router table fence, the "Fence/Bit" precision distance system and the "Fence stops" precision positioning system.

I took some 3 Tons of pics but I have to "Delete", "Sharpen", "Add Text" etc and it will take some time to post.

In between, I needed a sled to cut small (and not so small) pieces so I made one in 15~20 minutes from the "Floor Panels" left-over that I used for the router table.

I called it "All seasons sled" because temp and humidity changes are not effecting the sled runners that usually are expanding and contracting with humidity changes.

The sled is always tight, without any "Side play" and can be "re-adjusted" in seconds.

Because of the construction method, everything is very square to the blade and no need of "Two cut test" or "Five cut test"...it's dead 90°...as long as the blade is parallel to the miter slot and your triangle is accurate...

And last, it's sliding, actually half rolling, and is very, very easy to push-pull.

Many variations can be done on this sled and I leave it to your imagination (I have a few ideas).

Sorry but I did not take any pics of the WIP so if you have any questions, I'm here...

Regards

niki

Thanks again Niki.

Thanks again Niki.

Comment