I've been considering a 200 amp service upgrade.

How much do you think it would cost?

How do they handle wires that are to short for the new box???

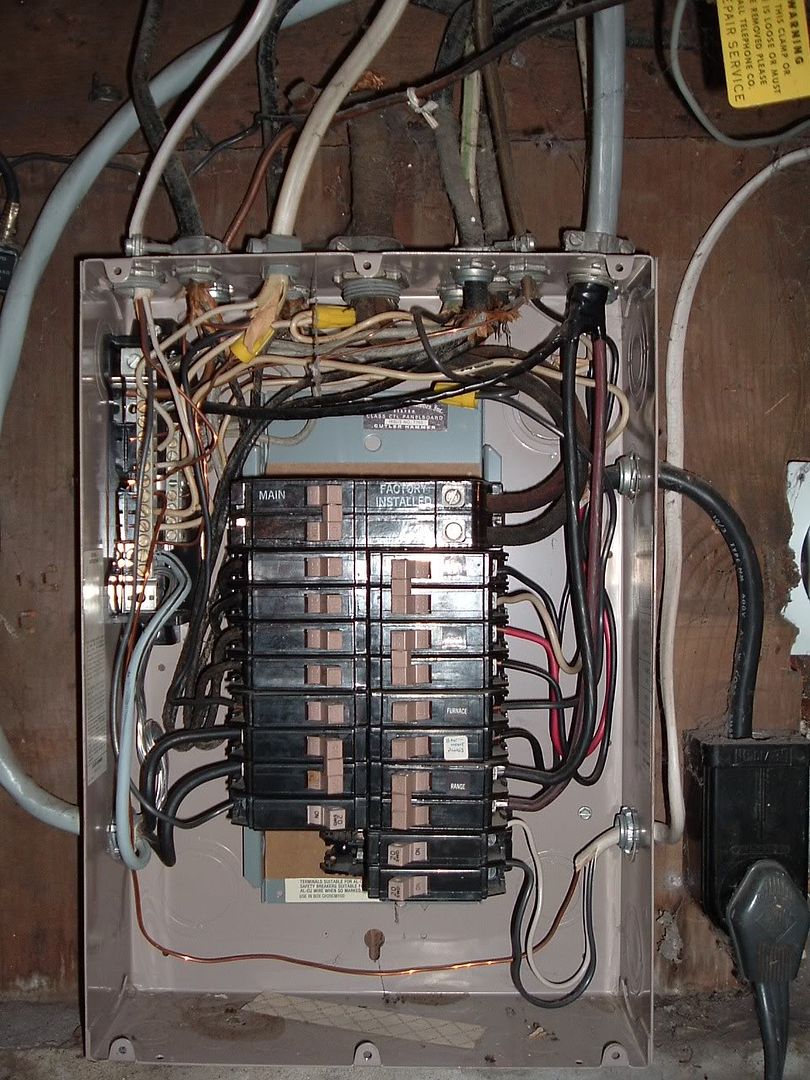

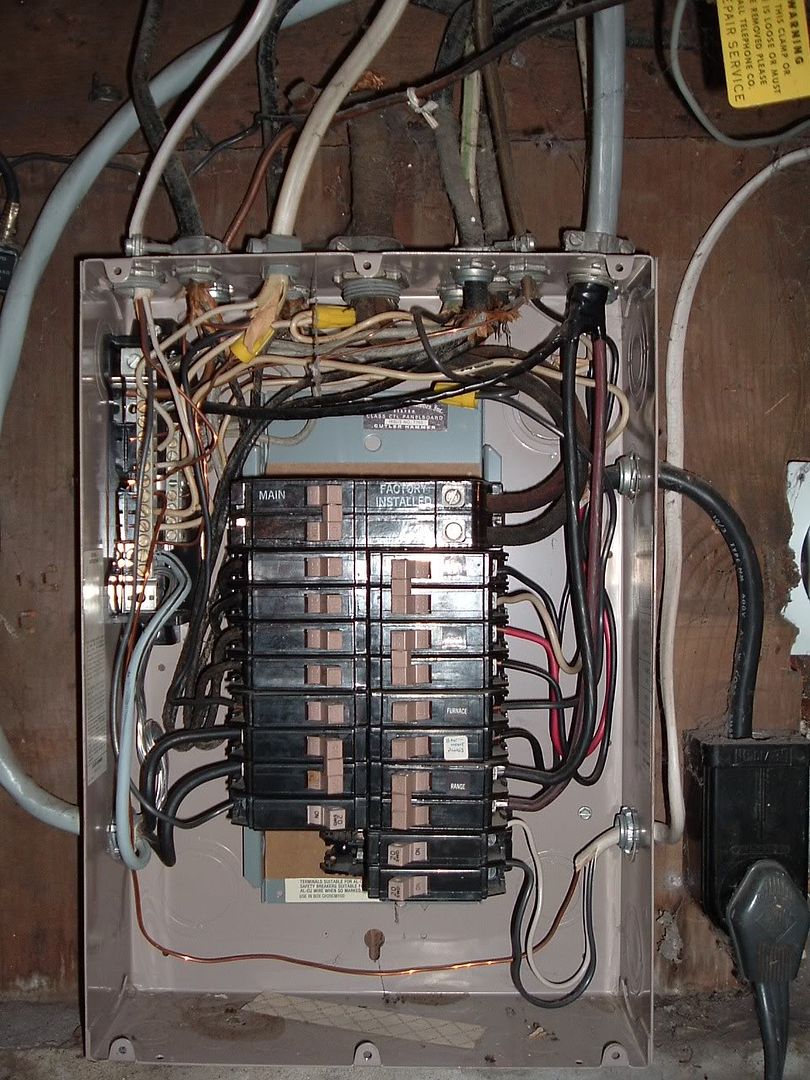

Here is pic existing box...

How much do you think it would cost?

How do they handle wires that are to short for the new box???

Here is pic existing box...

Comment