I was hoping someone would help a newbie with an idea.

I canít seem to find any shelving brackets that look nice enough to hold a 16in deep shelf so I think I have to try and build something.

Iím looking to build a shelf, I guess it would be more of an open cabinet to hold my home theater equipment. Weíre talking about 80 lbs worth of amplifiers, DVD players and such. It would be approx 74 inches long, 16 inches deep and made from either ĺ plywood or MDF.

I was looking at how my kitchen cabinets were built and I came up with this idea. Would this be able to support that much weight?

Iím thinking 3 inch screws on the top and bottom cleats into the studs.

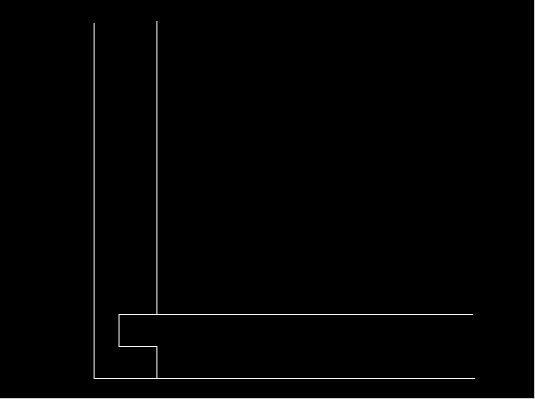

Hereís a bad drawing of if your were looking at it from the front.

Thanks!

I canít seem to find any shelving brackets that look nice enough to hold a 16in deep shelf so I think I have to try and build something.

Iím looking to build a shelf, I guess it would be more of an open cabinet to hold my home theater equipment. Weíre talking about 80 lbs worth of amplifiers, DVD players and such. It would be approx 74 inches long, 16 inches deep and made from either ĺ plywood or MDF.

I was looking at how my kitchen cabinets were built and I came up with this idea. Would this be able to support that much weight?

Iím thinking 3 inch screws on the top and bottom cleats into the studs.

Hereís a bad drawing of if your were looking at it from the front.

Thanks!

Black wallnut

Black wallnut

Two pieces of plywood sandwiched together, just cut out a pleasing shape with jig or band saw, separate pieces, space out to appropriate or pleasing distance, but wood blocks in between - glue, screw or nail (put in even distances) then bend thin plywood around the edges between the two pieces of ply to hide the blocking.

Two pieces of plywood sandwiched together, just cut out a pleasing shape with jig or band saw, separate pieces, space out to appropriate or pleasing distance, but wood blocks in between - glue, screw or nail (put in even distances) then bend thin plywood around the edges between the two pieces of ply to hide the blocking.

Comment