Howdy all!

What is the best way to rip round stock? I'm talking anything from 2" dowel up to 4" lodge pole style logs....ripping in half, to create basically half-round stock.

I've searched here, google, etc.... suprisingly, haven't found much on a safe way to do this.

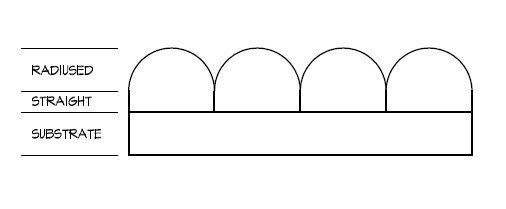

As an example of what a finished project would be, here's a pic of a door with half-rounds in it...

(Pic is from a craigslist ad for a Sante fe style entry door...so it may be an invalid pic link after awhile.)

Rat

What is the best way to rip round stock? I'm talking anything from 2" dowel up to 4" lodge pole style logs....ripping in half, to create basically half-round stock.

I've searched here, google, etc.... suprisingly, haven't found much on a safe way to do this.

As an example of what a finished project would be, here's a pic of a door with half-rounds in it...

(Pic is from a craigslist ad for a Sante fe style entry door...so it may be an invalid pic link after awhile.)

Rat

Comment