Okay, I've been wanting an outfeed table for my beloved BT31001. I've been using a roller stand for those long rip cuts, but for those shorter rips, I've tired of them dropping to the floor.

So, I looked at several other posts and some great ideas and nice craftsmanship, but I didn't want a hinge, something so big it would get in the way of portability for my little basement shop. I've got the BT mounted on a Herc-U-Lift and I really need to keep things quickly moveable and tucked out of the way as much as possible when not in use.

Last year we dumped an old refrigerator and for whatever "packrat" reasoning I had at that moment, I tucked the steel shelves aside.

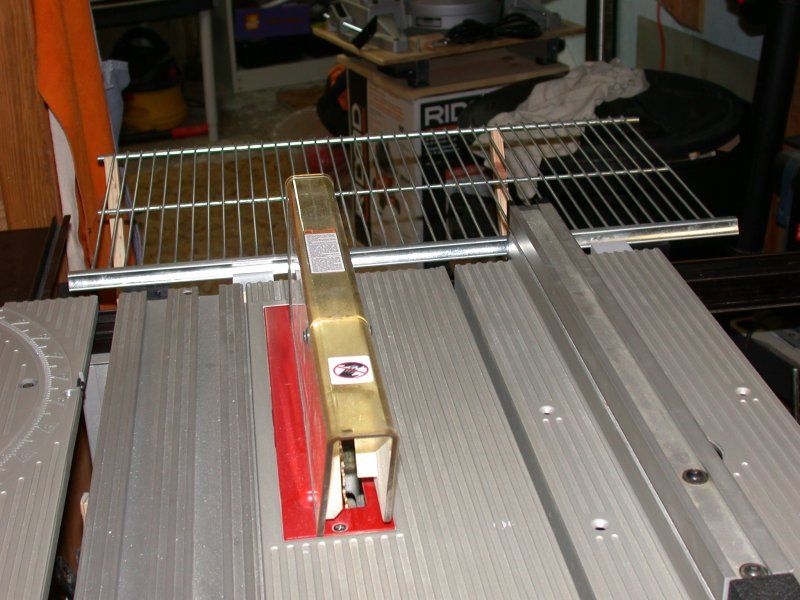

Well, I got to thinking about my outfeed table needs a couple of days ago and remembered the those shelves. So, here is something pretty simple I thought, as it's ready made and all I need is some method of attaching it to the rails. My first thought was for some hinge mechanism, but then I didn't want to have this not-to-pretty thing hanging back there.

What I came up with is a simple UHMW block from some scraps that I had purchased from L-V. Four pieces altogether, screwed together and mounted via a single bolt each to the small T-track area on the back of the rail.

The front decorative lip of the steel shelf, hooks over the mount and the rear is held up with a very simple wood support which is fabricated from so cut-off scrap. The top and bottom of the wood support is notched to fit the rack and the lower cross support on the BT. To keep every thing secure, I simply cut two small blocks which get tucked in between the rear of the saw table edge and the front edge of the shelf. It's not going anywhere and it strong enough to handle anything I'm going to rip on the BT.

Bottom line is it works, didn't take much effort and the price was right. What do you guys think?

CWS

So, I looked at several other posts and some great ideas and nice craftsmanship, but I didn't want a hinge, something so big it would get in the way of portability for my little basement shop. I've got the BT mounted on a Herc-U-Lift and I really need to keep things quickly moveable and tucked out of the way as much as possible when not in use.

Last year we dumped an old refrigerator and for whatever "packrat" reasoning I had at that moment, I tucked the steel shelves aside.

Well, I got to thinking about my outfeed table needs a couple of days ago and remembered the those shelves. So, here is something pretty simple I thought, as it's ready made and all I need is some method of attaching it to the rails. My first thought was for some hinge mechanism, but then I didn't want to have this not-to-pretty thing hanging back there.

What I came up with is a simple UHMW block from some scraps that I had purchased from L-V. Four pieces altogether, screwed together and mounted via a single bolt each to the small T-track area on the back of the rail.

The front decorative lip of the steel shelf, hooks over the mount and the rear is held up with a very simple wood support which is fabricated from so cut-off scrap. The top and bottom of the wood support is notched to fit the rack and the lower cross support on the BT. To keep every thing secure, I simply cut two small blocks which get tucked in between the rear of the saw table edge and the front edge of the shelf. It's not going anywhere and it strong enough to handle anything I'm going to rip on the BT.

Bottom line is it works, didn't take much effort and the price was right. What do you guys think?

CWS

Black wallnut

Black wallnut

Comment