I have everything setup on my new BT3100-1, but the riving knife. It is on, but I cannot get it lined up with the blade. It seems like it won't go far enough to the right (away from the SMT). I have all but one shim on the left side of the knife, but it still isn't enough. It looks to be just to the left of the carbide tips, and way to the left of the blade steel itself. Am I missing something, or is it just off?

Riving knife alignment question

Collapse

This topic is closed.

X

X

-

The purpose of the riving knife is to prevent the surface of the blade coming into contact with the stock after it has passed the center point, where the direction of travel of the blade is upwards. If the stock were to contact the blade disc, then it would throw the stock towards you, as the inherent friction would act like a transmission clutch disk and propel the stock once the friction took hold. As the blade is spinning at around 140MPH, that situation needs avoiding!

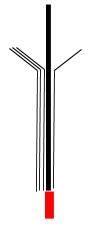

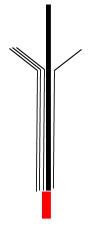

The teeth of the blade are wider than the disc for a number of reasons, so the riving knife (if narrower than the kerf - width of the teeth) needs to be set up so that it is in line with the edge of the teeth nearest to the fence. In the following diagram, the fence will be towards the bottom of the page, so you are looking down on the blade from the right-hand side (riving knife is black, saw disk is dark gray, teeth are light gray):

Some members have found that they needed to slightly bend their riving knife to align it. Hopefully, someone who has done this will spot this topic and post a comment.

Hope that helps. I've sent you a PM with a link to a related article.

Ray.Did I offend you? Click here. -

Once in a blue moon, someone has this problem. I had it on my 3000. There are two basic ways to fix it.

1. A few people "tweaked" the riving knife by bending it into position. By bending the riving knife 1/32nd or 1/16th of an inch, nothing is hurt and alignment is OK.

2. I bought a spacer that can be found at some hardware stores. Harbor Freight has saw blade bushing packs that worked just fine for me. It pushed the blade to the left just the right amount. Beware of using a washer as they might be too thick and they are not all manufactured to the tolerances of bushings.

Hank Lee

Hank Lee

Experience is what you get when you don't get what you wanted!

Comment

-

These guys are right on the money I think.

Some saws just came out unable to line up properly with the blade. If it is minor, then tweaking it a hair may work. That's a good item from HF. Don't think I have seen that before.

If all else fails, I do offer some brass blade shims on my site that should correct this situation. Not as cheap as HF. They are $5 a set which includes shipping.

http://www.leestyron.com/sharkryobi.php

Down toward the bottom of the page.

LeeComment

-

It sounds like my plan of carefully bending it over, then back at the top is the fix for now. Lee, I will probably grab some blade shims when I decide to upgrade to a shark. That is going to have to be just a little bit down the road, money wise.

Thanks all for the info.Joe SacherComment

-

Lee, that's great animation! I love stuff that doesn't even require a 4th grade reading level to understand.quote:Originally posted by Stytooner

These guys are right on the money I think.

Some saws just came out unable to line up properly with the blade. If it is minor, then tweaking it a hair may work. That's a good item from HF. Don't think I have seen that before.

If all else fails, I do offer some brass blade shims on my site that should correct this situation. Not as cheap as HF. They are $5 a set which includes shipping.

http://www.leestyron.com/sharkryobi.php

Down toward the bottom of the page.

Comment

-

Lee,

I ordered some shims. If I understand correctly, these are for the table saw blade. I guess I could shim the blade over with them but what I have done previously is cut up some brass shims for the blade into pieces I could use on the bolts that hold the splitter in place. My splitter is 0.090 so it has to be well aligned to work with thin kerf blades. The splitter was not parallel to the saw-blade without a shim or two. Now I can replace the blade shims I cut up - at a nice price.

JimComment

-

And if that $0.99 shim set is too rich for your blood, you can cut a shim out of a soda can. But I think a gentle bend in the right direction will fix you right up.

But I think a gentle bend in the right direction will fix you right up.

Regards,

Tom

Comment

-

Thanks Guys.

This problem has occured quite often with many different types of saw. With most they do have an adjustment for the splitters. Its sometimes quite involved, but still possible.

On the BT's its really not possible to adjust in the direction needed to line these up. Sometimes even without the shims in the splitter, you just can't get it far enough to the right. These brass shims allow you to install them to get the blade in the same plane as the riving knife. You don't need to mess with them but once. It will allow the inside edge of all your blades to line up the same way and in the same plane as the riving knife regardless of blade kerf thickness.

PS.

I always used to suggest bending, especially on the OEM riving knife. When you have a thicker knife like .090" its a little more difficult to bend, but still doable. If you already have a bunch of ZCTP cut for this now, bending may indeed be the best option. [8D]

I will get these in the mail ASAP. Tomorrow most likely. Thanks again. Lee

LeeComment

-

Well, the local HF didn't have the spacer package. So, I decided to order a space from Lee. While I was on his site, the Shark Guard jumped into my cart. I checked out before I noticed. At least that is my story and I'm sticking to it.

Real reason is that I tried a non-through cut, followed by a regular cut, with a guard install between. That was a real pain. I can see why people would leave the guard off. So rather than do that, I'll Shark Guard it.Joe SacherComment

-

Thanks Joe. I think this is a mistake that you may be grateful for.

You do know that Santa's Christmas list has already been checked twice?

Sleigh is being loaded for final Christmas delivery as I speak. You are looking at the first week of the new year for delivery. I hope this isn't a problem. Let me know if it is. Thanks again.LeeComment

-

I came across this problem today when setting up my BT3100. The image below shows how the shims were located from the factory. The blade is not centered, and the knife is to the right of the blade. Can I try and move the last shim with the others, and have the knife between the 4 shims and the holder?

ALSO, is this how the blade should align, or should it be exactly in the center?

Comment

-

You can take out the last shim if you need to. It just makes it a little more difficult to slip the riving knife into the bracket.

As far as alignment goes, anywhere behind the blade is okay, but it's optimal to have the right (fence side) of the knife in line with the teeth on the same side. Hard to get it perfect, but it can be done. Once you have it in line like that, you won't need to adjust it again for a different blade. Theoretically that is. Thats assuming all teeth hang over the edge of the platen the same amount. Lee

LeeComment

Footer Ad

Collapse

Comment