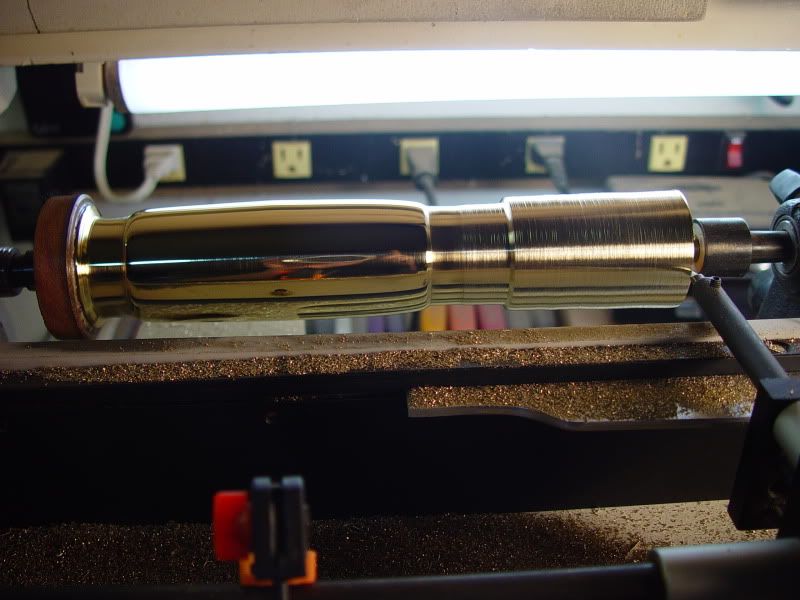

I turned the head out of a solid round 2" brass bar. The handle is a Beech ply that is called Compreg. It is soaked in resin and heated under high pressure. Same stuff as WWII propellers.

I mentioned in an earlier post that I was given 20+ 2"x2"x32" of this wood. It turns and finishes beautifully. Nothing but shellac and wax.

This one is the first of three that I was able to get out of the bar.

Steve

I mentioned in an earlier post that I was given 20+ 2"x2"x32" of this wood. It turns and finishes beautifully. Nothing but shellac and wax.

This one is the first of three that I was able to get out of the bar.

Steve

Comment