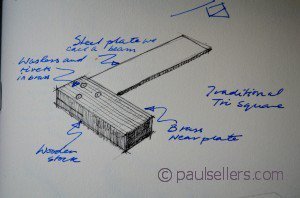

This old square belonged to my grandfather. It is ebony with a brass face and unfortunately not quite square. I could file down the blade somewhat and make it serviceable but the issue is really where the brass joins the ebony. There is a gap between them and the bass face is not straight or square.

Any ideas on how to make this workable or maybe I just use for rough "close enough" work.

Any ideas on how to make this workable or maybe I just use for rough "close enough" work.

Loring in Katy, TX USA

Loring in Katy, TX USA

Comment