Hi Thom

I think that, in a perfect world or on the drawing board, all the lines are perfect...and even a line hase some thickness...

In reality, it's a little bit different.

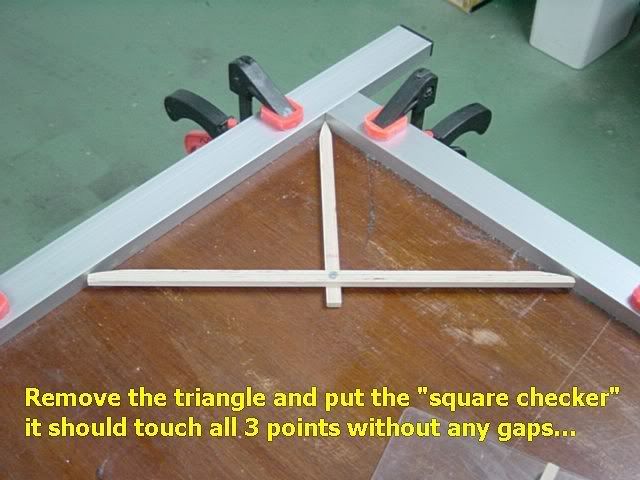

The pointers (apex) must be with virtually zero thickness to touch the same point at different angles but, the zero thickness point is very weak and will bent or brake or change shape with time.

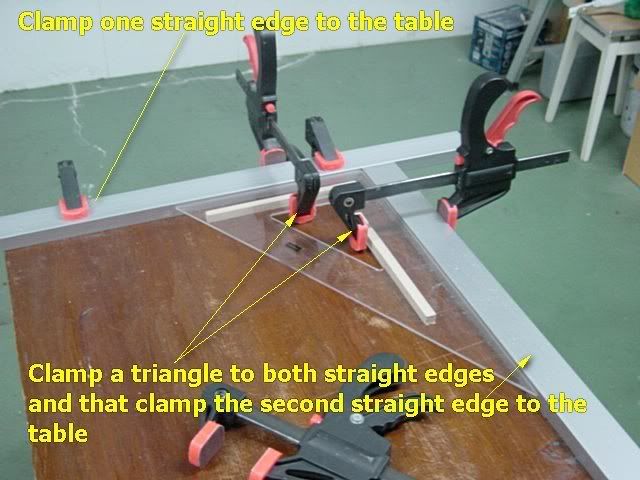

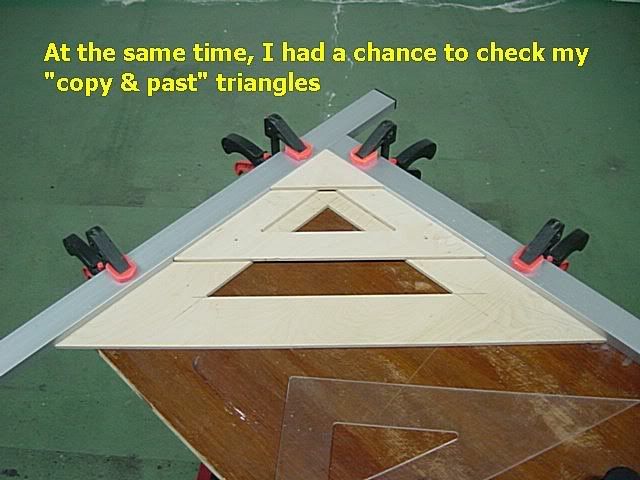

I understand that it's easier to calibrate the points but, if you look again at the way that I construct the "wheels" version, you will see that I'm actually "calibrating" them during the construction or more correctly, I drill the holes exactly at the same distance so there is no need to calibrate.

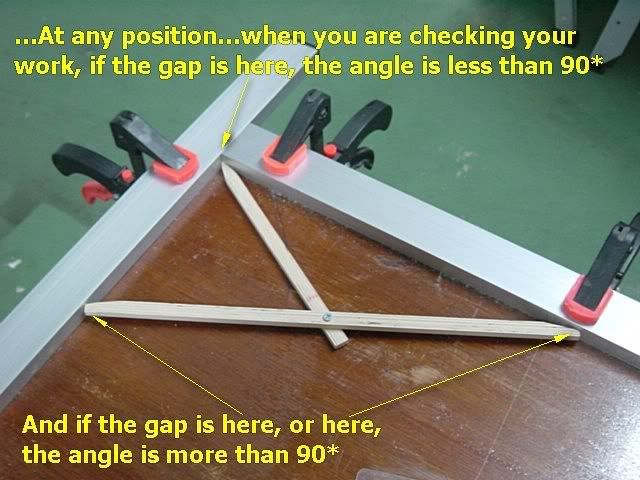

And if the holes are at the same distance and the wheels have the same diameter...all the three points are at the same distance and because it doesn't matter at what point the wheel touches the frame, I'll get always, at any angle, the correct reading of square.

Another benefit of the "wheels" method is that, the short arm will never touch the glue squeeze-out at the corner.

That's what I think but feel free to use the pointers if you feel so

Best Regards

niki

Checking for square

Collapse

This topic is closed.

X

X

-

Niki: This is the video I saw!

You had emailed me recently, as I was concerend over your other post where you used the rollers on the ends. The video you listed is where I first saw this device.

I still think the device is better and simpler with pointed ends.

The 'point' is, that the device is self-calibrating! You just pivot the short end around and make sure that it EXACTLY matches each end of the longer stick! This is why I like each of the ends to be pointed -- so you can easily MATCH them.

How about that? And folks pay how much for a square that is exactly 90?

IMHO.

ThomLeave a comment:

-

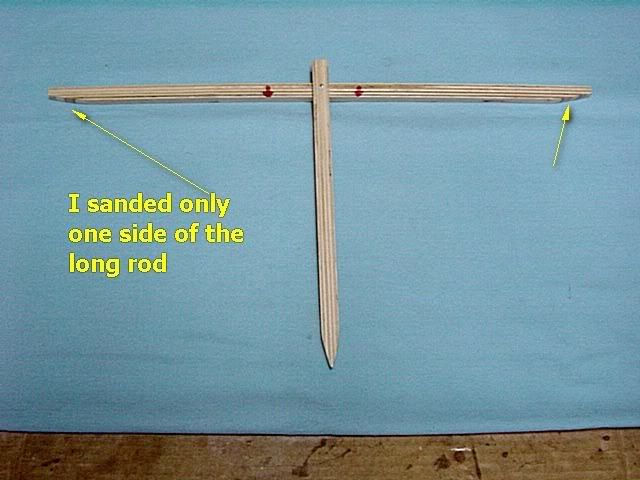

In any case, I'm using only one side so I did not want to sharpen the other side and maybe "over sharp". Also, I did not want to weaken it.

You can sharpen also the other side if you like to, I just did not see any need to do so.

Regards

nikiLeave a comment:

-

Why did you sharpen only the one side? Not yet done, or is there some other use, you haven't mentioned yet?

TIALeave a comment:

-

Thank you

Rob

"Fatal error occured in module......niki's brain....Press any key to continue"

I'm sorry, really bad presentation...but, you got it.

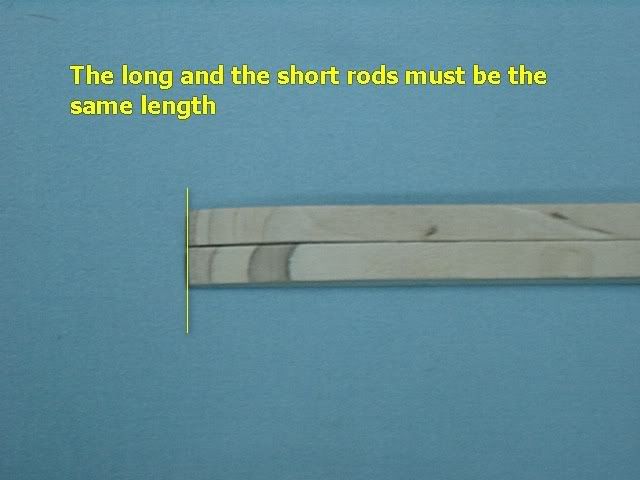

Actually, I chose some length for the long rod and drilled the hole approximately at the center (center of length), then, I drilled the hole on the short rod and adjusted (cut) the lengths on both sides of the long rod.

Regards

nikiLeave a comment:

-

I read "the long and the short rods must be the same length" and my brain had a blue screen error.

I figured out what you meant though.

Leave a comment:

-

Very nice mate....I saw a video of guy with one of those just the other day.Leave a comment:

Footer Ad

Collapse

Leave a comment: