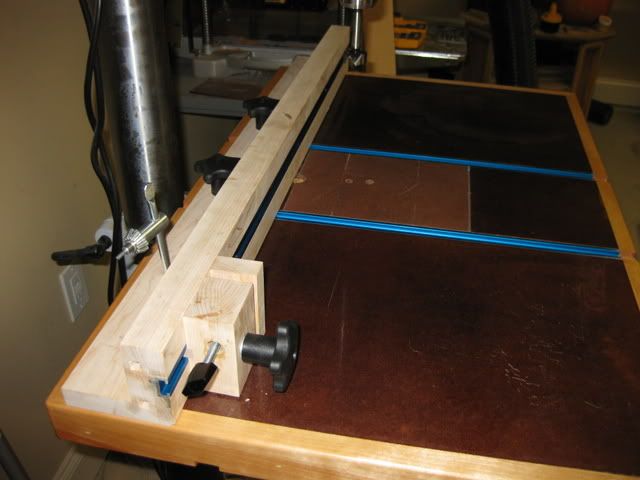

Unfortunately I followed the directions on the plans to the tee on this and really think it was poorly designed. The fence is 4 pieces. It's hard to explain without detailed pics, but the idea was to have a 1/2" thick face glued to 3 pieces with grooves to allow for rods to be inserted to attach extensions. The directions called for attaching the base to the face at a right angle. Then the other two pieces are placed behind it. The problem is there is nothing to hold it square so I had to face joint the fence and do some resawing to square everything up again.

If I decide to redo it I'm going to make it 3 pieces. I'll make the face 3/4 thick with grooves in the back for the extension rods and a rabbet at the bottom to help align the face to the base. Since I don't have a biscuit jointer I'd probably use pocket holes to attach the face and base. Then I'd cover the grooves in the back with a 1/2" backing and sand it flush.

If you don't want or plan on adding extensions just use a solid block or laminate to about an inch thick, cut a rabbet at the bottom and attach with biscuits, pocketholes or whatever you prefer.

Long story short, I wouldn't build the fence from the plans the same way at all.

If I decide to redo it I'm going to make it 3 pieces. I'll make the face 3/4 thick with grooves in the back for the extension rods and a rabbet at the bottom to help align the face to the base. Since I don't have a biscuit jointer I'd probably use pocket holes to attach the face and base. Then I'd cover the grooves in the back with a 1/2" backing and sand it flush.

If you don't want or plan on adding extensions just use a solid block or laminate to about an inch thick, cut a rabbet at the bottom and attach with biscuits, pocketholes or whatever you prefer.

Long story short, I wouldn't build the fence from the plans the same way at all.

Comment