One reason I bought my BT3100 is because the building that housed my shop at the time was very small. For most cutting operations, the stock footprint of a BT3100 was about as large a table saw as would comfortably fit. I was also attracted to the space-saving potential of the router mount in the stock accessory table.

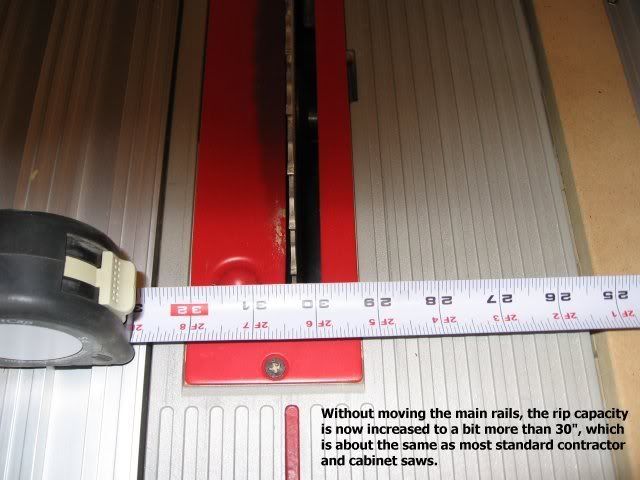

There were times, however, when I needed more rip capacity right of the blade. I got it in the usual way: by removing the SMT and moving the BT's rails as far to the right as they'd go. This worked well enough; but since it left me only about a foot of aisle space between the end of the rails and my workbench, I always had to return the rails to their standard placement when I finished my wider rips.

Eventually, I grew weary of having to move the rails around -- especially since I am one of those who uses the scale on the front rail; it became a real hassle to constantly recalibrate it. I had also decided that I wanted something a bit more sophisticated than the accessory table router mount, which I was using fairly heavily as a backup to my standalone router table. Lastly, I wanted to have a miter slot right of the blade, to complement the dual-slot table on the left.

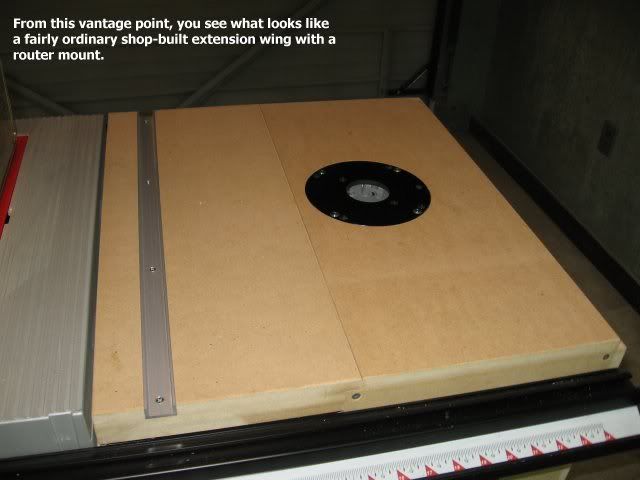

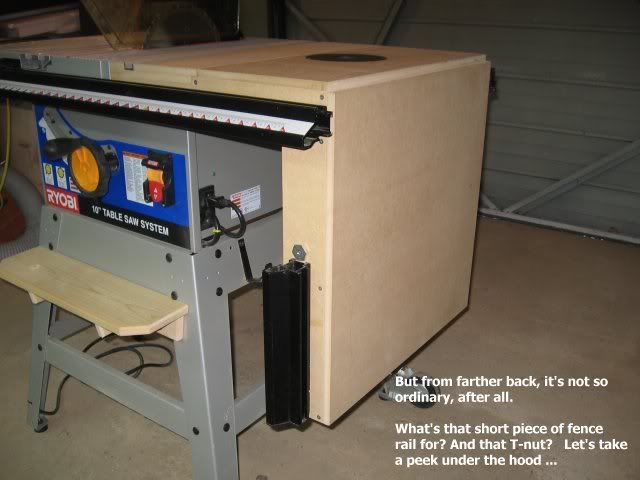

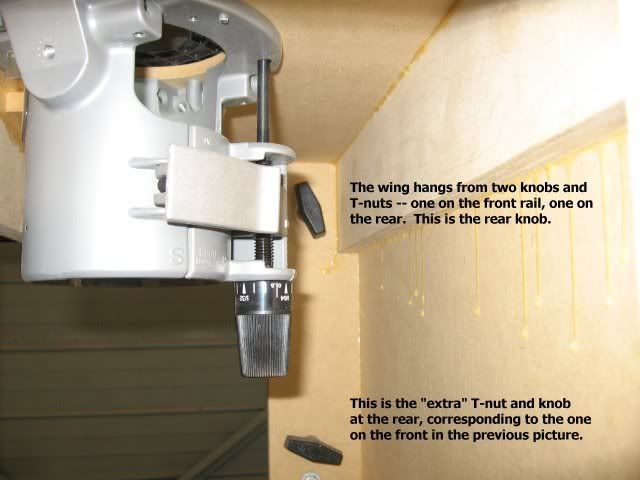

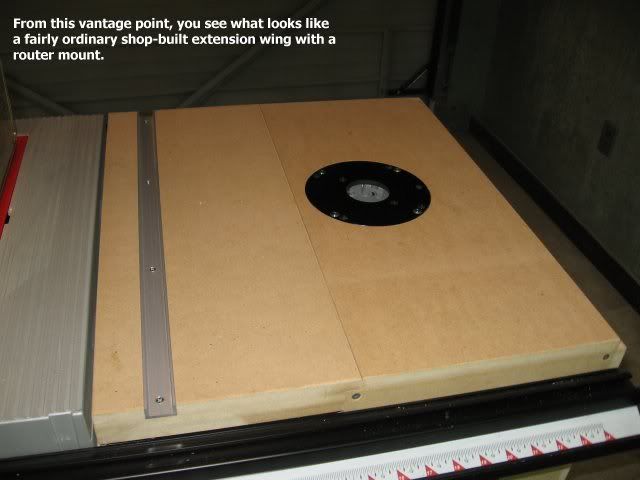

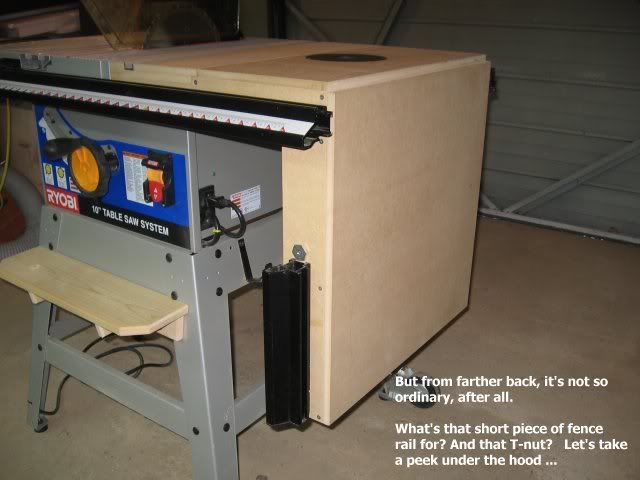

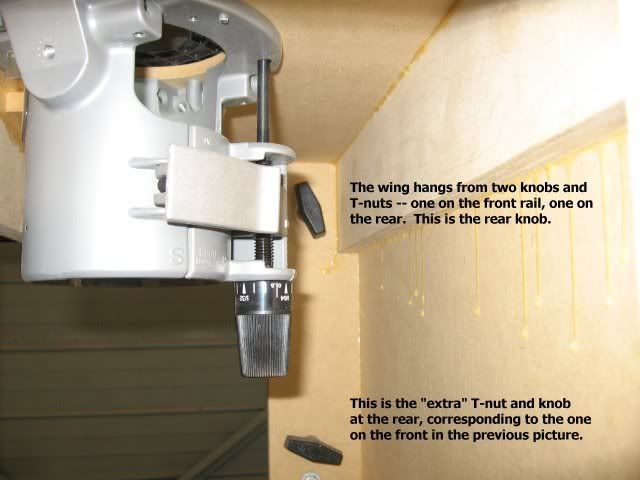

Almost exactly one year ago, on an idle day in the shop and seemingly out of nowhere, I was struck by an idea for a novel solution that would solve all these problems: keep the saw's footprint small most of the time; easily increase the rip capacity when necessary without removing the SMT or moving the saw's rails; improve the router mount; and add a miter slot right of the blade. Within a few hours, I had turned my raw idea into a working prototype, as pictured below.

As you look at the photos, please bear in mind that this is a rough prototype, designed and built in a quick-and-dirty fashion just to work out the dimensions and prove the concept. Pretty, it ain't. Perfect, neither. Even before I'd finished the prototype, I'd already begun to see things I would change and improve when I built the final, fancier version. Still, this prototype was and is fully functional, and has actually worked well enough that building that final, fancier version is yet another of the many projects I've yet to get around to ...

There were times, however, when I needed more rip capacity right of the blade. I got it in the usual way: by removing the SMT and moving the BT's rails as far to the right as they'd go. This worked well enough; but since it left me only about a foot of aisle space between the end of the rails and my workbench, I always had to return the rails to their standard placement when I finished my wider rips.

Eventually, I grew weary of having to move the rails around -- especially since I am one of those who uses the scale on the front rail; it became a real hassle to constantly recalibrate it. I had also decided that I wanted something a bit more sophisticated than the accessory table router mount, which I was using fairly heavily as a backup to my standalone router table. Lastly, I wanted to have a miter slot right of the blade, to complement the dual-slot table on the left.

Almost exactly one year ago, on an idle day in the shop and seemingly out of nowhere, I was struck by an idea for a novel solution that would solve all these problems: keep the saw's footprint small most of the time; easily increase the rip capacity when necessary without removing the SMT or moving the saw's rails; improve the router mount; and add a miter slot right of the blade. Within a few hours, I had turned my raw idea into a working prototype, as pictured below.

As you look at the photos, please bear in mind that this is a rough prototype, designed and built in a quick-and-dirty fashion just to work out the dimensions and prove the concept. Pretty, it ain't. Perfect, neither. Even before I'd finished the prototype, I'd already begun to see things I would change and improve when I built the final, fancier version. Still, this prototype was and is fully functional, and has actually worked well enough that building that final, fancier version is yet another of the many projects I've yet to get around to ...

LCHIEN

LCHIEN Loring in Katy, TX USA

Loring in Katy, TX USA

Comment