Just thought I would introduce myself.

My name is Trevor I am really new to wood working but falling in love with it. I have had a couple projects but nothing I am extremely proud of. I have created a fish tank stand, a hood for an aquarium and then completely botched another fish tank stand.

All I really have to work with is a circular saw I have been hinting to my wife pretty hard that o would love a table saw for Christmas. I have also recently picked up a pocket hole kit for my next project which is a dining room table

Sent from my iPhone using Tapatalk

My name is Trevor I am really new to wood working but falling in love with it. I have had a couple projects but nothing I am extremely proud of. I have created a fish tank stand, a hood for an aquarium and then completely botched another fish tank stand.

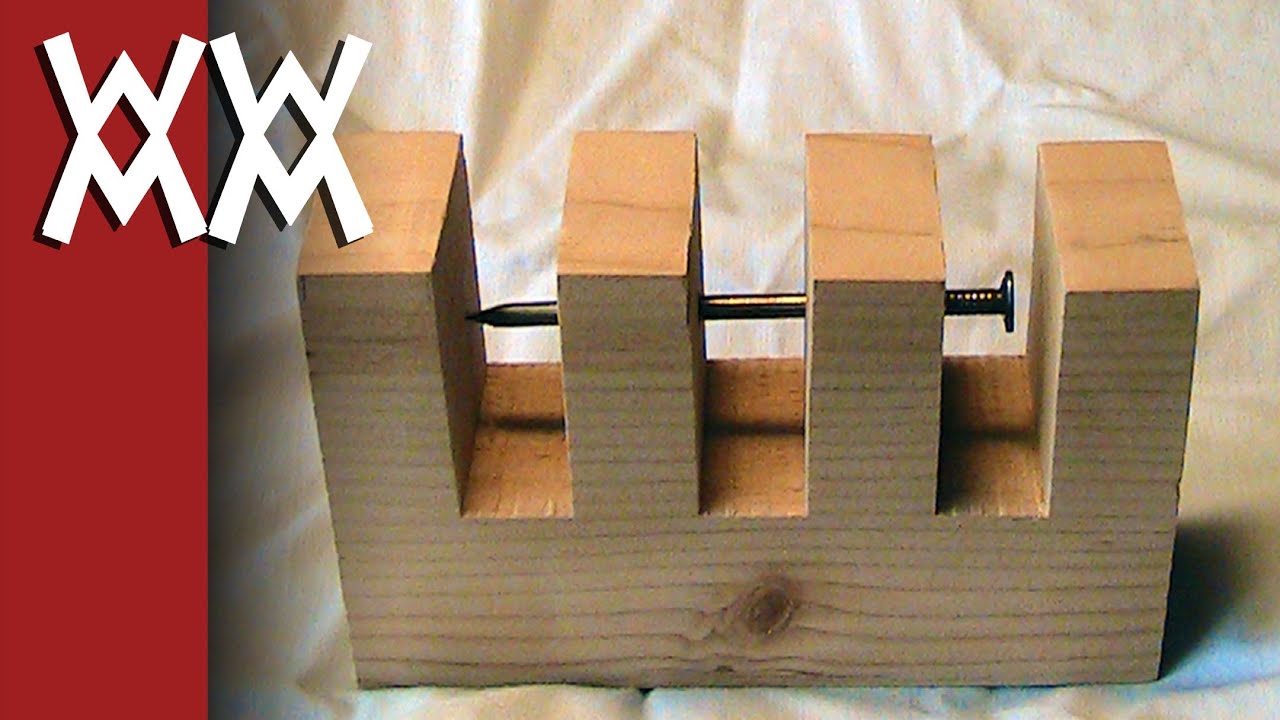

All I really have to work with is a circular saw I have been hinting to my wife pretty hard that o would love a table saw for Christmas. I have also recently picked up a pocket hole kit for my next project which is a dining room table

Sent from my iPhone using Tapatalk

twistsol

twistsol

Comment