I have some really nice flexable steel rulers that are old. They are in 1/10'ths of inch. If that doesn't mix you up nothing will. I am glad that 1/10ths are not used for anything but rain gauges.

MFT'ing my Sawstop

Collapse

This topic is closed.

X

X

-

Actually it would make a lot more sense than 8ths and 16ths and such... At least the frac to decimal would be easy!

Comment

-

Agreed, if the US had stuck to the 1/10 per inch it would have been better, and a lot easier on our brain to ease into the metric sys. Opps.. we still do use 1/10 ths, all of my machinist tools and equip are in .1, .01, .001 etc.Comment

-

Why 20mm instead of 3/4? I now have 4 20mm dogs, so my main goal of able to fixture work has been accomplished. Could have been done with 3/4 as well. The 20mm is because I have my eyes on the festool clamping elements wihch use 20mm holes.Great addition! Looks very functional.

Curious though.

Why 20mm holes instead of the standard 3/4" holes? I would think 20mm would make things like holdfasts harder to find.

Why MDF? I would be worried about it being too prone to sagging with any sort of weight, and swelling with changes in humidity.

Why MDF? That is what I had. I originally planned to support with a grid structure underneath, but this would have made some other clamping options less than ideal. I am supporting the MDF on all sides with the 8020 to mitigate this. Worst happens and I discover some sag -- the top is easily replacable with something stiffer. I just need to keep the thickness at the edge to about 3/4 to sit on the 8020.Comment

-

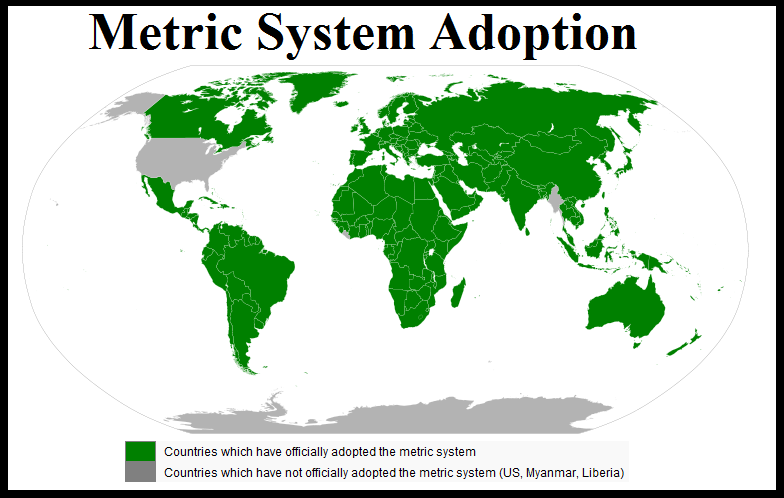

I was in grade school in the late 70s/early 80s and we were essentially told that "in a few years" the whole US would be using the metric system exclusively. 30+ years later and I'm still waiting, lol.

What surprises me most isn't that we still have some imperial units around, it's that how "oddball" the metric system still is in everyday life.

-TimComment

-

Beautiful setup. Can you comment on what you think of the horsepower of the Sawstop compared to the BT3? I thinking of a similar upgrade but want to be confident the bigger saw is really better.

(yeah I'll go searching as I'm sure this has been discussed)

JonComment

-

I have the 3hp sawstop. I recall noticing the feeling of no resistance when ripping a 2x4. With the exact same blade (Forrest WWII full kerf) on the BT3K, I recall the saw pushing back. Sorry I can't quantify this, and it could just be faulty memory as well.Comment

-

Regarding the sag issue using mdf for mft type tops, I used this resource http://www.woodbin.com/calcs/sagulator.htm

So far I have had no issues.

Last edited by bigstick509; 05-06-2014, 07:34 AM.

Last edited by bigstick509; 05-06-2014, 07:34 AM.

Mike

"It's not the things you don't know that will hurt you, it's the things you think you know that ain't so." - Mark TwainComment

Footer Ad

Collapse

Comment